In the LED (Light Emitting Diode) industry, Bin parameters serve as the core indicators for evaluating product performance, bridging the gap between manufacturing and application. From high-end displays to everyday lighting, from automotive headlights to medical equipment, the Bin classification of LEDs directly impacts product quality, cost, and suitability for various scenarios. This article delves into the definition, technical rationale, and practical applications of this parameter system, aiming to present a comprehensive, professional, and highly readable exploration.

Bin parameters of LEDs are foundations of achieving top quality LED display.

Binning, or sorting, is a standardized classification method for the photoelectric parameters of LEDs during manufacturing. Due to inherent variations in semiconductor materials, parameters such as luminous flux, color temperature, and wavelength can fluctuate within the same batch of LED chips. Manufacturers employ binning technology to divide these parameters into multiple intervals (e.g., luminous flux Bin, color temperature Bin, chromaticity coordinate Bin), assigning specific codes (e.g., “A1,” “B2”) to each interval. For instance, an LED model might have a luminous flux ranging from 1000 to 3000 mcd, which manufacturers could divide into bins like AA (1000-1500 mcd) and AB (1500-2000 mcd) for customer selection.

LED binning typically encompasses the following key parameters:

Luminous Flux (Lm): Measures the total amount of light emitted by an LED, with higher Bin values corresponding to greater brightness.

Color Temperature (K): Defined in Kelvin, it determines the warm or cool tone of light, such as 2700K for warm white and 6500K for cool white.

Chromaticity Coordinates (x, y): Based on the CIE 1931 chromaticity diagram, they precisely describe the color position of light, ensuring color consistency.

Color Rendering Index (CRI): Evaluates a light source’s ability to render object colors accurately, with high-end lighting requiring CRI≥90.

Forward Voltage (VF) and Wavelength (WL): Influence circuit design and color performance.

International standards (e.g., ANSI) classify white LEDs into multiple BIN areas based on color temperature, with each area corresponding to specific color tolerance ranges. For example, within the 5300-6000K range, sub-areas like B0 and B1 are defined, matching human sensitivity to color differences (e.g., a 585nm wavelength difference≥1nm is detectable). Manufacturers can also develop internal standards based on market demand, such as customized binning for specific color points.

Kinglight provides various LEDs with different bins for different application scenarios.

Binning technology significantly reduces batch variations by screening LEDs with consistent performance. For instance, in Micro-LED displays, without strict binning, brightness or color differences between adjacent pixels can cause a “dirty screen” effect. By using mixed-binning techniques and Demura algorithms to compensate for wavelength differences, brightness uniformity can be improved to over 98%, meeting the demands of precision displays like AR/VR.

Different applications have varying needs for Bin parameters:

High-end Scenarios: Museums require precise matching of chromaticity coordinates for artifact color fidelity, while film and television lighting demands high CRI bins (CRI ≥ 95).

Low to Mid-range Scenarios: Home lighting can accommodate broader color temperature bins to reduce costs, while automotive lighting necessitates high-reliability bins for heat resistance and longevity.

High-Bin products command a premium due to their superior performance. For instance, within the same LED model, a brightness Bin AA might cost 30% more than Bin AD. Manufacturers use binning to stratify their product lines: high-Bins for professional markets and low-Bins for large-scale demand, balancing R&D investment and profit margins.

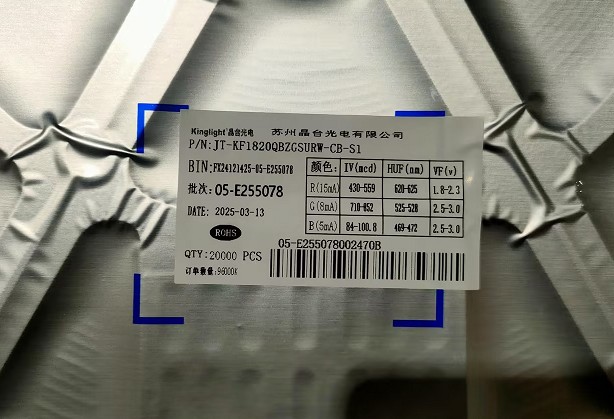

Bin number and R/G/B light parameters are clearly stated on Kinglight LED’s aluminum foil bag.

In LED displays, binning directly determines image quality. For a 4K screen, without strict chromaticity coordinate binning, color deviations across different regions can degrade overall viewing experience. Laser repair technology can increase yield to 100%, achieving “zero dead pixels” display. Additionally, creative displays (e.g., transparent screens, spherical screens) rely on flexible bin combinations to achieve dynamic lighting effects.

Commercial Lighting: High-end hotels use visual binning techniques to eliminate subtle color differences detectable by the human eye, creating a comfortable lighting environment.

Specialized Lighting: Plant growth lights require specific wavelength bins (e.g., 660nm red light for photosynthesis), while medical lighting depends on high-CRI bins to render tissue colors accurately.

Automotive Lighting: Adaptive headlights need dynamic color temperature bin adjustment, while interior ambient lighting uses multi-bin mixing to achieve 16 million color personalization.

Micro-LED: Spectrometers (e.g., LED die sorters) enable nanometer-level wavelength detection, driving advancements in wearable devices and ultra-high-definition displays.

Traditional binning relies on manual sampling, which is inefficient and prone to errors. Next-generation sorters can detect 20+ parameters simultaneously, sorting millions of chips per hour with ±0.5nm precision. For example, VISTAR Display’s mixed-binning + Demura technology uses AI algorithms to compensate for parameter fluctuations in real-time, significantly reducing Micro-LED mass production challenges.

Kinglight utilizes advanced equipment for LED sort and bin classification

Industry standards (e.g., ANSI color temperature bins) facilitate supply chain collaboration, while flexible binning supports small-batch customization, such as developing special wavelength light sources for research institutions.

Binning optimizes material utilization and reduces waste. For instance, low-efficiency Bin LEDs can be directed to secondary markets (e.g., indicator lights), enabling resource recycling.

From an individual LED chip to grand display scenarios, Bin parameters act like a “genetic code,” permeating every step of manufacturing, selection, and application. They reflect not only the precision of semiconductor technology but also the dynamic balance between market demand and technological innovation. In the future, as binning accuracy improves and costs decrease, LEDs will unlock potential in more fields (e.g., space lighting, brain-computer interfaces), continuously rewriting humanity’s interaction with light.

Related reading:

9 common procedures of LED packaging >>>