As global sustainability goals and carbon neutrality strategies accelerate, the LED display industry is undergoing a deep transformation centered around energy efficiency. Leading this shift is AOTO Electronics, which has pioneered a multi-layered energy-saving technology system built on AI-driven algorithms and system-level optimization. This article explores AOTO’s innovation journey and the broader trends shaping energy-efficient LED displays, while spotlighting a vital component at the heart of power savings — the LED package.

AOTO Mini LED P1.5 Indoor Rental Screen

From outdoor billboards and stage visuals to smart transportation systems, LED displays have become integral to modern visual infrastructure. However, their extended runtime and brightness requirements have turned energy consumption into a critical issue. A single large-format LED display can consume tens or even hundreds of kilowatt-hours per day — increasing operational costs and becoming a target of energy regulation.

Traditional energy-saving strategies — such as simple brightness reduction or time-based control — often fall short in dynamic environments. Truly intelligent energy efficiency must start from the ground up: chip architecture, system design, and real-time smart algorithms.

AOTO’s approach to energy savings transcends individual technologies. The company has developed a comprehensive framework combining advanced chip design, optimized driver architecture, and AI-powered power management.

AOTO has adopted 80nm process chips, a leap forward from the commonly used 150nm chips in the market. These chips offer higher transistor density and shorter signal paths, resulting in significantly reduced driving current and lower energy consumption — while also enhancing processing power and display quality.

With common cathode architecture, AOTO enables independent current control for RGB channels, significantly reducing power loss. When paired with flip-chip technology, thermal paths are shortened and efficiency is improved. Furthermore, pixel-level current control via advanced driver ICs ensures precise energy regulation and better synchronization in complex scenarios.

AOTO’s unique AI Dynamic Energy-Saving Mode monitors ambient light, content type, and user interaction in real time. It dynamically adjusts PWM duty cycle, brightness, grayscale, and contrast. For example, during low-light scenes, the system lowers the drive current and puts certain regions into sleep mode. Internal testing shows temperature reductions of up to 50% and energy savings reaching 48%.

AOTO AI-assisted precision LED screen brightness control

For applications such as digital billboards or control centers that operate 24/7, AOTO integrates black screen mode and smart standby technology.

When the system detects idle content or signal interruption, it enters an ultra-low-power mode: the driver chip dims to zero brightness, while the processor, scan card, and power supply switch to standby. Power usage drops below 1W, with savings of up to 80%. This not only cuts energy costs but also extends the display’s operational lifespan.

While system-level technologies like AI and driver ICs are essential, true energy efficiency begins at the LED source level. Each LED package — as the direct emitter — plays a crucial role in the display’s total power consumption.

Among the key players in energy-efficient LED packaging is Kinglight, a long-established specialist in SMD LED technology. Kinglight has introduced a range of innovations that push LED efficiency to new heights without compromising performance:

Kinglight focuses on ultra-compact SMD designs such as 1010 and 0606, which are widely used in fine-pitch LED displays under P1.5. By optimizing the light-emitting structure and using high-efficiency materials, Kinglight’s LEDs deliver higher brightness and luminous flux per watt — effectively reducing the total system power requirements.

By selecting chips with low forward voltage (VF) and optimizing the packaging process, Kinglight’s LEDs operate stably under lower voltages. When combined with common cathode systems, this results in minimal energy loss and improved power supply efficiency.

Kinglight enhances heat dissipation through bottom-contact package designs and optimized material selection, resulting in lower thermal resistance. Reduced heat buildup not only slows brightness decay but also minimizes the need for active cooling — contributing to overall system energy savings.

With stringent binning protocols and rigorous quality control, Kinglight ensures tight uniformity in brightness, voltage, and wavelength across LEDs. This reduces the need for display-side calibration and power compensation. Moreover, Kinglight’s low-decay products maintain high luminous efficiency over long operating periods, reducing the need for frequent replacements and conserving energy in the long term.

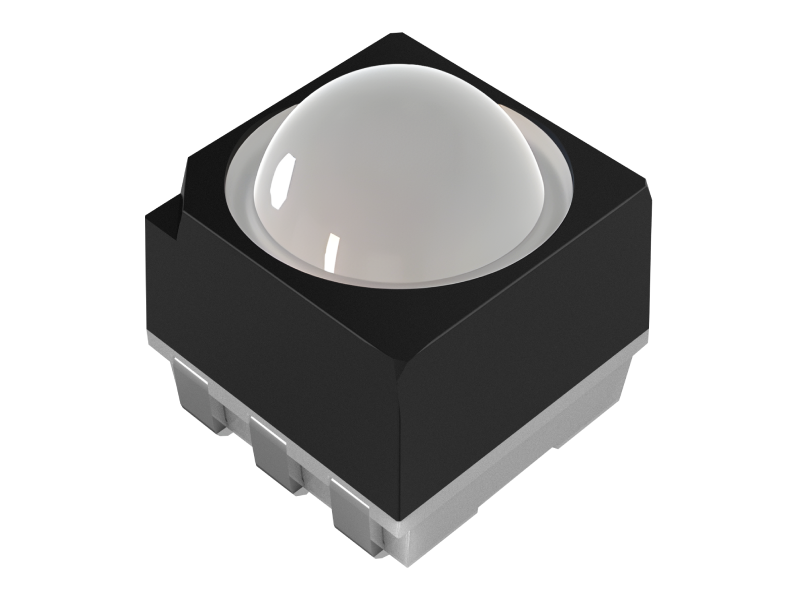

Kinglight has also developed high-intensity lens-type LEDs, such as the 2727-A4-T70. These designs feature a convex lens over the RGB chips, increasing light transmittance and focusing scattered light toward the center. This boosts luminous intensity by over 50%, enabling high-brightness output at lower currents, ideal for outdoor displays that require extreme brightness with lower power draw.

Kinglight 2727 Lens LED

These packaging advancements not only optimize individual LED performance but also offer significant efficiency benefits to display manufacturers. In today’s industry, energy efficiency is as much about materials science and packaging innovation as it is about systems and algorithms.

AOTO’s exploration of LED display energy efficiency represents more than just power savings. It reflects a system-level capability that spans chip design, driver architecture, intelligent algorithms, and cutting-edge LED packaging.

Looking ahead, energy efficiency will no longer be a “bonus feature” — it will be a core competitive advantage. And achieving that advantage requires cross-disciplinary collaboration between display integrators like AOTO and LED innovators like Kinglight.

The age of intelligent energy-saving displays is here — and it’s shining brighter, but greener than ever.