LED packaging refers to the process of enclosing LED chips within a protective housing or package that provides electrical connections, thermal management, and protection. LED packaging plays a crucial role in determining the performance, reliability, and functionality of LEDs. Here’s an overview of key aspects related to LED packaging.

The LED chip is the core component of an LED package. It is a semiconductor device that emits light when electrically driven.

LED chips are typically made of materials such as gallium nitride (GaN) or indium gallium nitride (InGaN) that determine the emitted light’s wavelength and color.

LED chips are extremely small and fragile, usually ranging from a few hundred micrometers to a few millimeters in size.

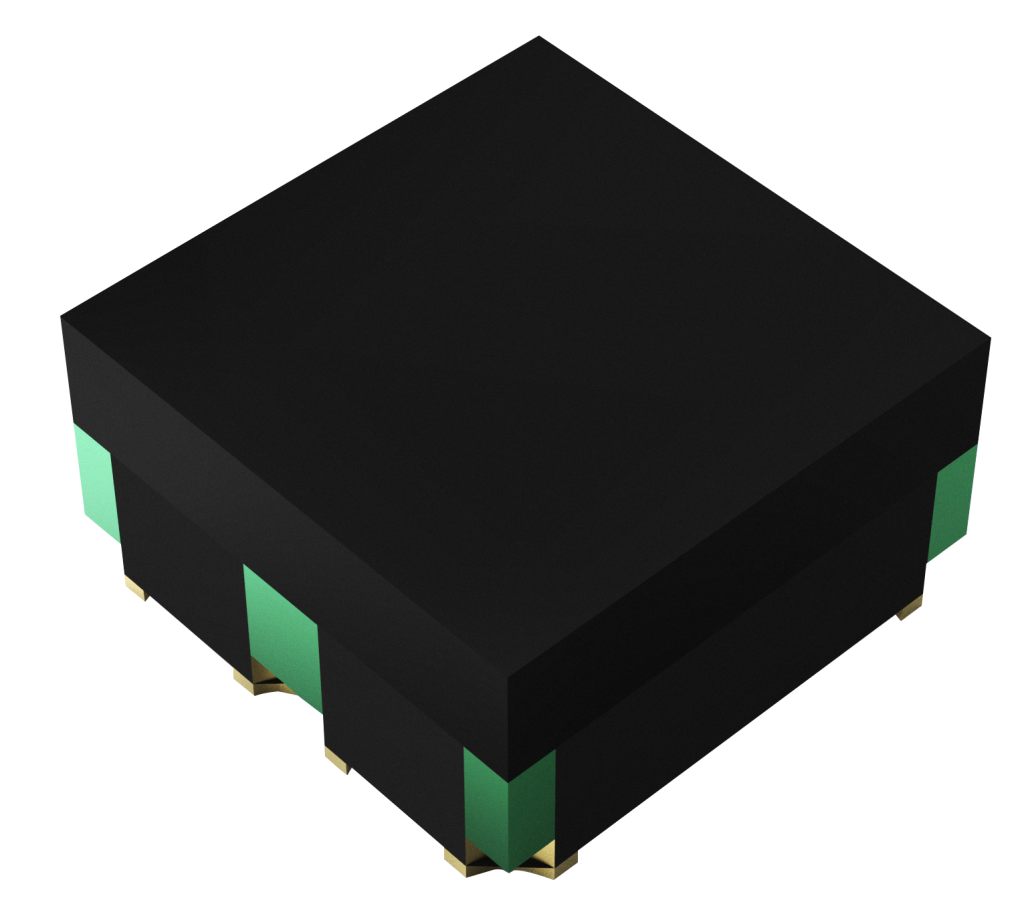

There are various types of LED packages, each designed for specific applications and requirements.

Common LED package types include through-hole LEDs, surface-mount device (SMD) LEDs, chip-on-board (COB) LEDs, and high-power LEDs.

Through-hole LEDs have leads that pass through holes in the PCB for soldering.

SMD LEDs are compact and can be mounted directly on the PCB surface.

COB LEDs involve mounting multiple LED chips directly onto a substrate, providing high brightness and thermal management advantages.

High-power LEDs are designed to handle higher currents and emit intense light output.

Kinglight LED Packaging – Wire Bonding Line

LED packages have electrical leads or pads that allow for electrical connections to the external circuitry.

Through-hole LEDs have leads that are soldered onto the PCB.

SMD LEDs have metal pads on the bottom surface for surface mounting onto the PCB using solder paste and reflow soldering.

COB LEDs and high-power LEDs often require additional wiring or soldering for electrical connections due to their higher current handling capabilities.

LED packages generate heat during operation, and efficient thermal management is critical for their performance and longevity.

LED packages incorporate heat sinks, heat spreaders, or thermal pads to dissipate heat away from the LED chip.

Some high-power LED packages may require additional cooling mechanisms such as fans or heat pipes to maintain optimal operating temperatures.

LED packages may include optical components, such as lenses or diffusers, to control the light output pattern and enhance efficiency.

Encapsulation materials, such as epoxy or silicone resin, are used to protect the LED chip from environmental factors and provide mechanical stability.

LED packages undergo rigorous testing and quality control procedures to ensure their performance, reliability, and adherence to specifications.

Testing includes electrical characterization, luminous flux measurements, color quality assessments, thermal performance evaluations, and more.

LED packaging technology continues to evolve to meet the demands of various applications.

Advancements include miniaturization, higher power densities, improved thermal management, and enhanced optical designs.

Trends in LED packaging focus on improving efficiency, color accuracy, and reliability while reducing costs and form factors.

Kinglight dedicates in LED packaging and offers a wide variety of LEDs for LED screen manufacturing industry

LED packaging is a complex process that requires expertise in materials science, electrical engineering, and optics. It directly impacts the performance, durability, and versatility of LEDs, making it a critical aspect of LED technology development and application.

Related reading: