In the first and second parts of this article, we have described in detail some matters that need to be paid attention to in LED packaging and LED SMT operations. Next, we will further explore the operating details of LED in actual application and aging, so as to have a more comprehensive understanding of how to reasonably maintain the performance of LEDs and ensure the long-term performance stability of LED modules or LED screens.

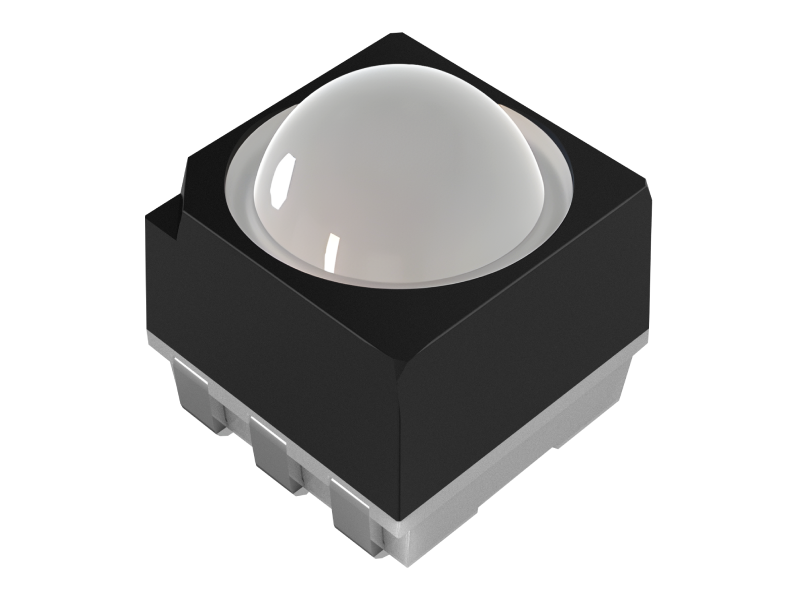

Kinglight 2727-A4-T70 LED with transparent lens

III – Application and Aging Considerations of LEDs & LED Displays

There are many things to pay attention to during the application of LEDs and aging of LED displays to ensure their stability and keep optimized performance.

- LED is a moisture-sensitive component. The PPA bracket (or BT substrate) and epoxy resin (polymer material) used for packaging have hygroscopic properties, so it will absorb moisturein the surrounding environment before and after SMT process.

- Taking moisture-proof measures for the LED before SMT process can prevent the epoxy resin from peeling off, reduced life of the LED,and even LED failure due to moisture expansion caused by high temperature when passing through the reflow oven; moisture-proofing after SMT can prevent the LED chip from failing due to electrochemical reactions when powered on in a humid environment.

- General method of LED module aging

3-1. Indoor LED products: The initial LED module aging time is 1-2 days; the cabinet or the entire screen aging time is 3-5 days.

3-2. Outdoor LED products: LED modules age for 1-2 days in the early stage; cabinets age for 2 days after glue filling, and the entire screen ages for 3-5 days.

3-3. For the specific aging method, LED screen manufacturers can adjust it according to the actual technical requirements. It should be noted that long-term, full-grayscale white balance lit-up is strictly prohibited to avoid aggravating the light decay of LEDs.

- During the aging process, if abnormal situations occur such as LEDsnot lighting up or lighting up in unwanted same colors, the specific cause can be determined by bare LED testing and replacing the position of the defective LEDs; check whether there is cold soldering; in addition, the intensity of the aging program can be increased to observe related problems and provide immediate feedback to the corresponding LED manufacturers.

- LED products should be hung for aging in time after rain aging. It is strictly forbidden to store them directly in the warehouse without any treatment.

- Temperature protection: attenuation of the performance of LEDs will accelerate under high temperature conditions, and its own stress will also increase; if it is exposed to high temperature for a long time, it is easy to fail. Generally speaking, the LED screen should be used in an ambient temperature of -30℃ – 50℃; during use, ensure that the temperature of the surfaces of LEDs does not exceed 55℃ and the pin temperature of the LEDs does not exceed 75℃.

- Reverse voltage protection: Generally speaking, the reverse leakage current of LED is very small and will not affect normal use. If the LED is subjected to a large reverse voltage shock, it will accelerate electrochemical corrosion, the LED will be damaged, and the reverse leakage current will increase rapidly, causing the LED screen to light up in unwanted same colors; therefore, it is necessary to pay attention to controlling the reverse voltage during design. Generally speaking, the reverse voltage loaded on the LED should not exceed 1.5V to minimize the high-frequency reverse voltage shock to the LED chip in the circuit.

- Use LEDs in suitable environments: IndoorLEDs are different from outdoor LEDs; do not use indoor LEDs in environments with high humidity, or high acidity, or high alkalinity, This will avoid irreversible damage to the indoor LEDs and prevent shortened service life of the LEDs.

- If the LED modulesor LED cabinets are stored for too long and are not installed into LED displays for operation in time, the LED modules or cabinets must be placed in an oven and baked at 70℃ x24 hours to completely dehumidify before the screen ages normally.

- Guidance for the end users of LED screens: The LED screenshould be often lit. When the LED screen is lit, the LED chip heats up, and moisture cannot intrude into the LEDs; if the LED screen is not used for a long time (usually means 5-10 days, slightly different due to environmental and climatic factors), it is necessary to gradually increase the brightness for dehumidification. The specific method is as follows.

10-1. Connect the LED screen to the power supply and let the screen warm up for 2-4 hours.

10-2. turn on LED screen and let it run at level 10 brightness for 4-6 hours.

10-3. increase brightness to level 20 for 6-8 hours

10-4. increase brightness to level 30 for 8-10 hours.

10-5. increase brightness to level 40 for 10-12 hours.

10-6. increase brightness to level 50 for 12-14 hours.

10-7. increase brightness to level 70 for 14-16 hours.

10-8. increase brightness to level 90 for 16-18 hours.

10-9. increase brightness to level 120 for 18-20 hours.

10-10. increase brightness to level 150 for 20-22 hours.

10-11. increase brightness to 200-level, and appropriately reduce or extend the operation duration according to the actual situation, environment, climate, screen-off time, etc.

It should be noted that due to the huge differences in the degree of moisture absorption of LED screens, the above methods sometimes won’t work. Therefore, the best thing to do is to turn on the LED screen for 1-2 hours every day to ensure it not absorbing too much moisture, and always keep a record over the operating status of the LED screen, which will also help a better maintenance of your LED screens.