Nowadays, LED screens are popular and being widely used in supermarket, shopping malls, bus and train stations, airports, stages, concerts and other events for displaying eye-catching advertising and eye catching contents, etc. While we’re getting quite familiar with LED screens surrounding us, but a few of us might know how LED screens come to the places we visit or pass by. In this article, we’ll go through 8 procedures to transform LEDs into LED screens.

Stage display

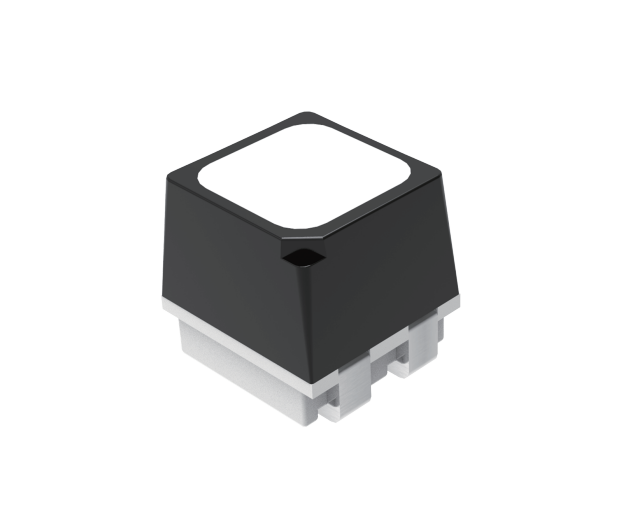

LED modules consist of an array of individual LEDs mounted on a printed circuit board (PCB) or other substrates.

The LEDs are placed in a matrix pattern on the PCB, typically using surface-mount technology (SMT) or through-hole technology.

The LEDs are electrically connected to the PCB using wire bonding, soldering, or other techniques.

Additional components, such as driver chips, capacitors, and resistors, may be added to the PCB to support the operation of the LEDs.

The assembled LED modules are tested to ensure proper electrical connections and functionality.

LED modules are typically mounted within a frame or cabinet structure to form a complete LED screen.

Frames or cabinets are constructed using lightweight and durable materials, such as aluminum or steel.

The size and configuration of the frame or cabinet depend on the desired dimensions and installation requirements of the LED screen.

The LED modules are precisely placed within the frame or cabinet, ensuring proper alignment and spacing between the modules.

The modules are secured in place using screws, clips, or other fastening methods to ensure stability and durability.

Electrical and data connections are established between the LED modules and the control system.

Power cables and data cables are routed and connected to each LED module, providing the necessary power supply and control signals.

The cables are organized and hidden within the frame or cabinet to maintain a neat and professional appearance.

Kinglight offers a wide variety of LEDs for LED screens manufacturing industry

LED screens require calibration and configuration to ensure optimal performance and uniformity.

Calibration involves adjusting the color and brightness settings of the LEDs to achieve consistent and accurate display output.

Configuration includes setting up the screen resolution, refresh rate, and other parameters according to the desired requirements.

The assembled LED screen undergoes thorough testing and quality control procedures.

Testing involves checking the functionality, color uniformity, brightness, and other performance aspects of the screen.

Quality control measures ensure that the screen meets the manufacturer’s standards and specifications.

The LED screen is installed and mounted in the desired location, following proper installation guidelines and safety protocols.

Mounting options can include wall mounting, ceiling suspension, or integration into larger structures or display systems.

The LED screen is connected to a content and control system, allowing for the display of desired content.

Content can be controlled through software or hardware-based control systems, enabling the display of images, videos, text, or other visual elements.

It’s important to note that the specific procedures and techniques may vary depending on the type of LED screen, such as indoor or outdoor screens, as well as the manufacturer and design specifications. The above steps provide a general overview of the procedures involved in turning individual LEDs into functional LED screens.