In the previous article, we’ve talked about the high quality raw materials being used for the manufacturing of Kinglight KS series LEDs, which can be the basic reason that why these LEDs can provide 5 years extra-long warranty than common varieties. In fact, there are more technical reasons. For example, Kinglight KS series LEDs have passed more strict quality control procedures before being delivered to the clients. Here we’ll list 5 important testing procedures to ensure the stability and durability of Kinglight KS series LEDs.

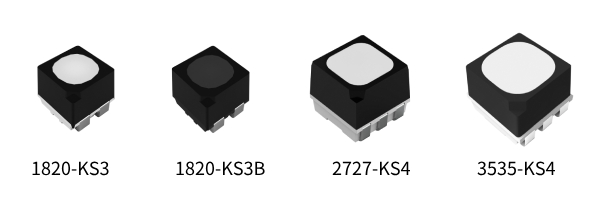

Kinglight KS Series LEDs

First, Kinglight KS series LED will go through a strict 504-hour high temperature and humidity testing. This will ensure the performance of Kinglight KS seres LEDs at extreme temperature and humidity conditions.

High temperature and humidity test for Kinglight KS series LEDs

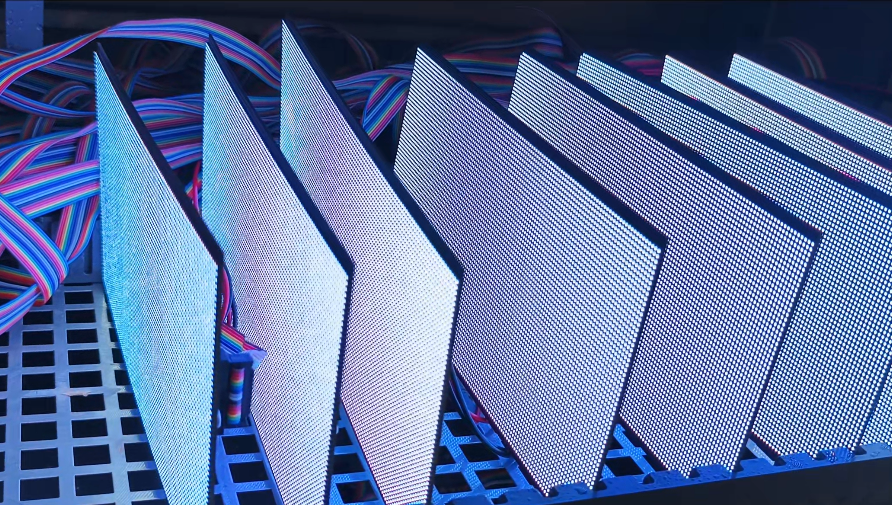

Second, to further ensure the resistance of huge temperature drop and rise, Kinglight QC department will proceed another 504 hours of high and low temperature cycle testing with KS series LEDs.

Before and after the testing, an ultrasonic scanning will also perform for comprehensive examination of KS series LEDs.

High & Low Temperature Cycle Testing

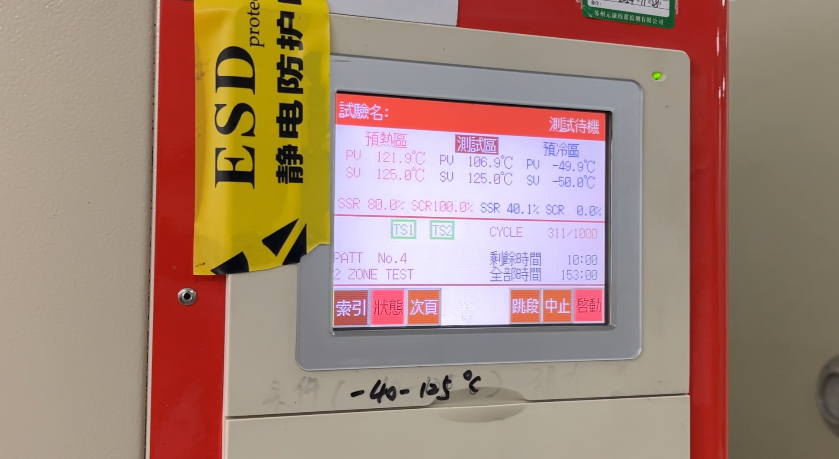

Third, Kinglight KS series will proceed with a 200 round thermal testing, which is hot and cold shock test between -40 degrees centigrade and 125 degrees centigrade. This will ensure the performance of Kinglight KS series LEDs at extreme temperature conditions.

Thermal Shock Testing for Kinglight KS Series LEDs

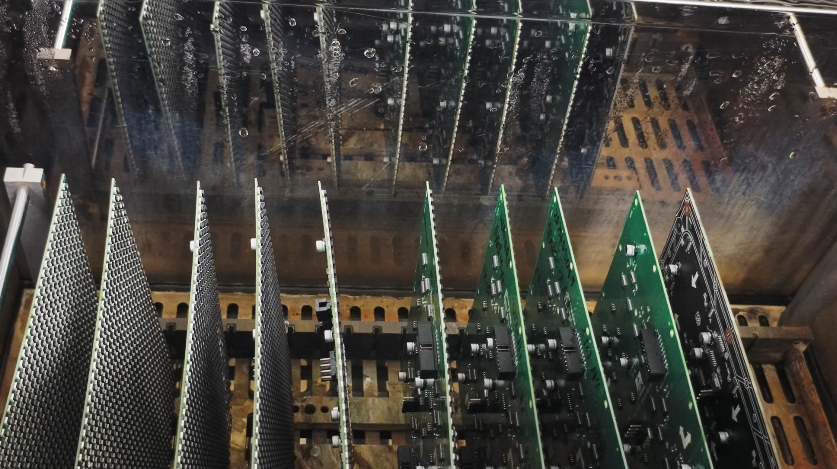

Fourth, another 168 hours water bath test will be conducted on Kinglight KS series LEDs in an electric constant temperature water bath chamber. This will ensure the performance of Kinglight KS series LEDs at extreme humid and hot conditions.

Water Bath Test for Kinglight KS Series LEDs

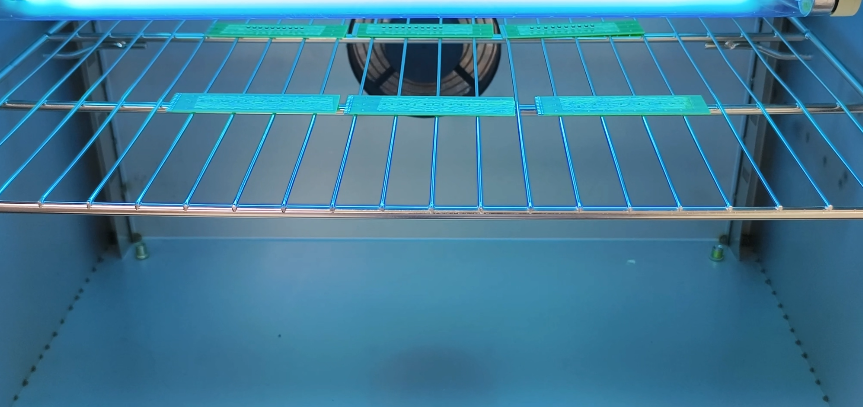

Fifth, a 504 hours ultraviolet weathering test will be done to check and ensure the resistance of UV weathering of KS series LEDs.

After the test is completed, Kinglight KS series LEDs remain over 90% brightness, which meets the demand for long time operation and long service life.

Ultraviolet Weathering Test for Kinglight KS Series LEDs

In addition, Kinglight KS series LEDs do not only pass the above mentioned strict QC testing procedures, but also pass various of other types of testing, such as red ink testing, reflow heat resistance, colloid shedding test, salt spray test, salt water air tightness test, display effect test, etc.

In conclusion, Kinglight KS series LEDs have to pass more strict testing at extreme conditions to ensure their performance in different application scenarios, to meet the demand for operation at extreme environmental factors, and for a prolonged service life. That’s why Kinglight KS series LEDs can provide 5 years extra long warranty, which is much longer than the warranty (possibly one or two years, or even less) of common varieties of LEDs.

Video origin: https://www.youtube.com/watch?v=OBqbYdp5xl0