DIP and SMD are two commonly seen LED screen technologies on the market.It might be difficult for you to make a choice between them. No worry! Here in this article, we’ll give a detailed description over what DIP and SMD LED are, and tell the differences between the two different LED display technologies.

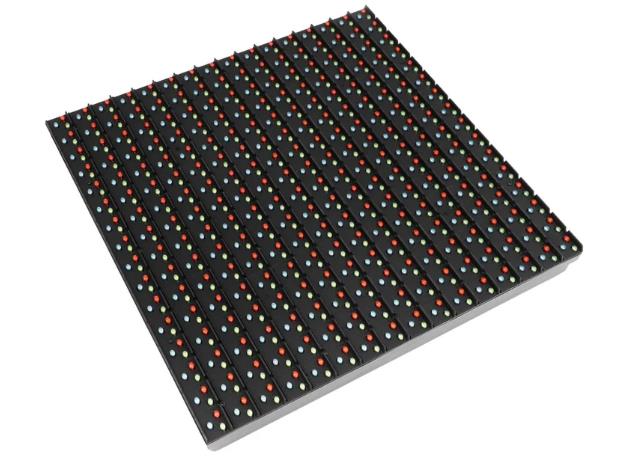

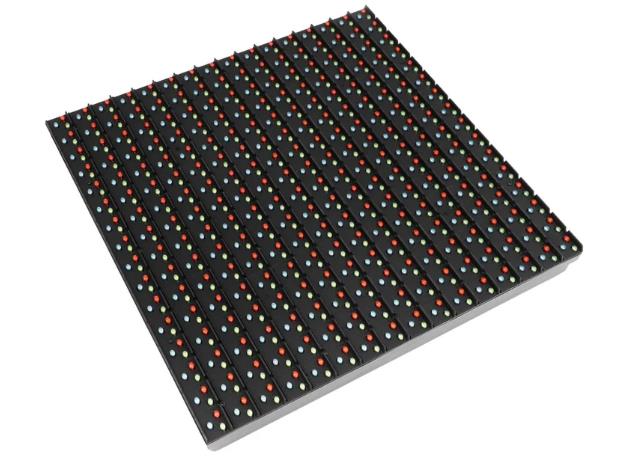

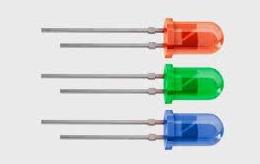

We can clearly see R, G, B LEDs on a DIP LED screen.

What is a DIP LED screen?

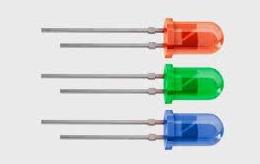

DIP LED screen refers to a type of screen using DIP LEDs. DIP here stands for dual in-line package. In dual in-line package, R, G, B LEDs are mounted into plastic package with two long pins.

What is an SMD LED screen?

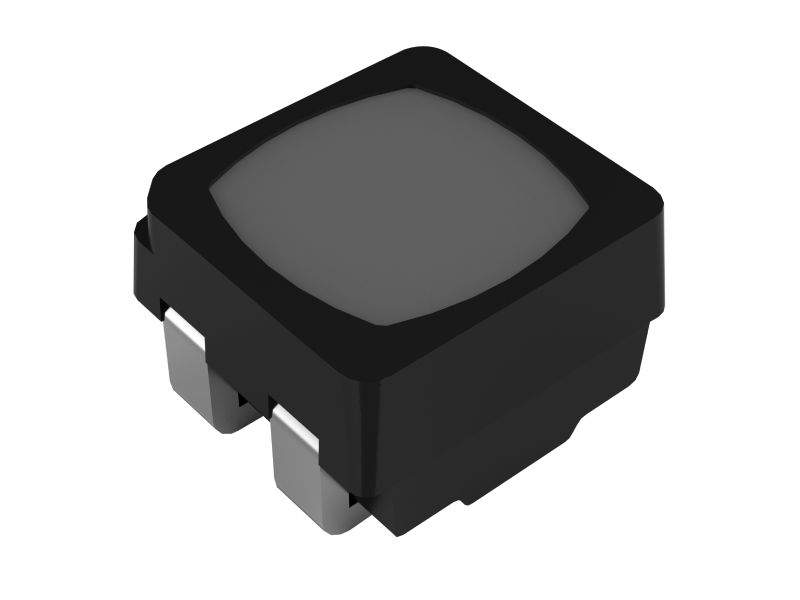

An SMD LED screen utilizes SMD LEDs to form a pixel matrix. SMD is the abbreviation for surface mount device. An SMD LED usually includes R, G, B LED chips to make a single pixel of the screen, and is directly mounted onto the circuit board, and becomes a pixel of the SMD LED screen.

The differences between DIP LED and SMD LED?

The differences between DIP LED and SMD LED are mainly reflected in the following aspects.

- Design: DIP LEDs are more like LED bulbs with pill shaped design and long pin connections, we usually need 3 LEDs to form an all-color pixel; on the other side, an SMD LED is more compact in design with very short pins, and it includes R, G, B LED chips in one device and can work as a pixel independently.

- Display performance: SMD LED has more compact design, and the space between the R, G, B LED chips are much smaller, thus SMD LED offers more smooth color transition than DIP LED.

- Application scenarios: DIP LED is more robust and mostly used for outdoors, such as an LED signage. SMD LED excels in image quality, and is more application for making indoor LED displays, especially high resolution ones.

- Colder soldering issue: DIP LED is plugged into the PCB with two long pins, and cold soldering issue seldom happens on DIP LED; but an SMD LED is directly onto the PCB with very short pins, and cold soldering issue is more likely to happen on SMD LEDs.

- Brightness: A DIP LED is larger than an SMD LED, and of course, we get a much higher brightness on a DIP LED screen. For example, an outdoor signage made of DIP LEDs can have a brightness over 7,500 nits, or even 10,000 nits, but an outdoor billboard made of SMD LEDs can reach only around 6,000 nits.

- Heat dissipation: the two long pins offer much better heat dissipation for a DIP LED. Better heat dissipation often means longer life for electronics. Thus, it’s understandable that an DIP LED screen lasts longer than an SMD LED screen.

- Power consumption: it is tested that at the same specification, a DIP LED screen consumes 1/3 less power than an SMD LED screen.

- Viewing angle: SMD LEDs have much wider viewing angle than DIP LEDs, usually reaching around 140 degrees in both horizontal and vertical, while DIP LEDS reaching only 120 degrees in horizontal and 60 degrees in vertical.

- Resolution: SMD LEDs can be packed much tighter than DIP LEDs, hence an SMD LED screen often has higher pixel density than a DIP LED screen, which means we get higher resolution on an SMD LED screen.

- Viewing distance: as mentioned above, SMD LEDs are more compact in size and offer higher resolution. Most SMD LED screens have smaller pixel pitches between 1mm and 7mm. So the viewing distance for SMDLED screens is usually much closer than DIP LED screens with much higher pixel pitches.

- Durability: DIP LEDs not only excel in heat dissipation, but also in the performance of withstanding vibration, impact, and mechanical stress due to their through hole mounting designs. On the other hand, SMD LEDs are less resistant to impact. That is to say, DIP LEDs are more durable than SMD LEDs.

- Cost: SMD LEDs are more complicated designed than DIP LEDs, thus they are costlier. But as technology keeps developing, SMD LEDs are much more affordable than before. SMD LED screens also cost higher in maintenance and repairing.

DIP vs SMD LED, which one to choose

After going through the above paragraphs, guess you should get a better understanding over DIP LEDs and SMD LEDs. So it’s easier to make a choice between the two different LED display technologies.

If you need higher resolution and watch the screen in a closer distance, then an SMD LED screen is what you want; if you want an outdoor screen for longer viewing distance, then you should use a DIP LED screen.