Counterfeit products remain a persistent challenge across many industries, particularly within the electronics and semiconductor sectors. In the LED display supply chain, counterfeit LED packages pose serious risks to product performance, reliability, and long-term safety.

As a leading LED packaging manufacturer, Kinglight has made LED authenticity verification a long-term, standardized initiative. By operating a dedicated LED testing laboratory and offering professional identification services, Kinglight actively helps end users reduce the risks associated with counterfeit and substandard LED products.

As 2025 comes to an end, this report summarizes Kinglight’s anti-counterfeiting efforts over the past year and shares key insights to help the industry better identify and prevent counterfeit LEDs.

Kinglight has consistently invested in anti-counterfeiting initiatives and continues to provide free LED authenticity testing services to customers and partners each year.

During a mid-year review in 2025, testing results showed that approximately 13% of submitted samples were counterfeit, despite a relatively limited number of submissions. By the end of the year, updated statistics revealed that 26% of all samples tested in 2025 were identified as counterfeit, indicating a noticeable rebound.

This figure closely mirrors the 27% counterfeit rate recorded in 2024, suggesting that the overall market situation has not significantly improved.

These results highlight an important reality: the presence of counterfeit LEDs tends to fluctuate and rebound when market participation and enforcement remain insufficient. Anti-counterfeiting cannot be effective without broader involvement from end users, integrators, and distributors.

The ultimate objective of counterfeit prevention is to continuously reduce—and ultimately eliminate—fake LED products from the market, thereby protecting end users from financial loss, performance instability, and potential safety hazards.

Combating counterfeit LEDs requires collective participation. Increased sample submission and verification are essential steps toward a healthier and more transparent LED supply chain.

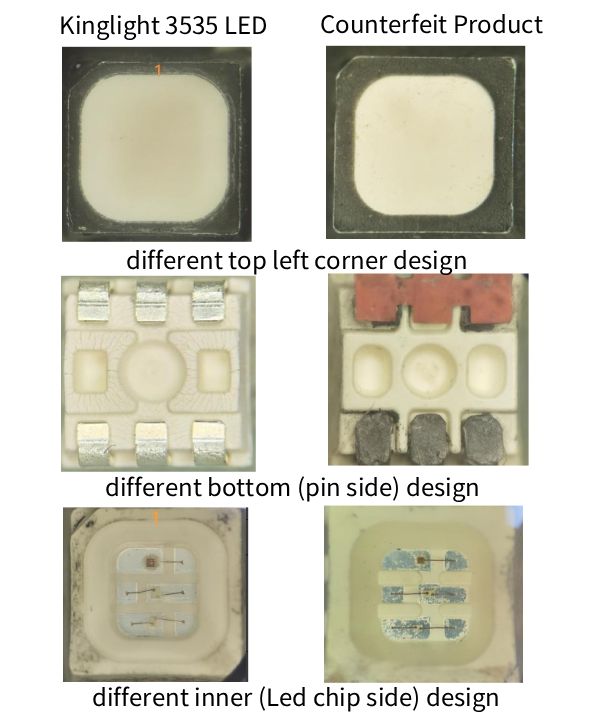

Due to limitations in manufacturing processes and materials, counterfeit LEDs often fail to replicate the internal structure of genuine products.

Using 3535 LED as an example, microscopic comparisons between genuine Kinglight LEDs and counterfeit samples clearly reveal structural inconsistencies. These differences become immediately apparent under magnification, making accurate identification possible through professional testing.

This demonstrates that when authenticity checks are performed, counterfeit LEDs have nowhere to hide.

Kinglight designs and manufactures LEDs using high-quality materials, optimized structures, and strict quality control procedures. This ensures consistent optical performance, stable electrical characteristics, and long service life.

Counterfeit LEDs, however, are typically constrained by:

As a result, counterfeit LEDs often exhibit:

In more severe cases, these deficiencies may introduce safety risks, increasing maintenance costs and jeopardizing project reliability.

Moving into 2026, Kinglight will continue to offer free LED authenticity testing services, reinforcing its commitment to customer protection and product integrity.

We encourage customers, partners, and industry professionals to actively participate in counterfeit prevention efforts. Every submitted sample contributes to reducing counterfeit circulation and strengthening trust across the LED display ecosystem.

Kinglight remains dedicated to handling every test with professionalism and transparency, upholding its principle of customer-first service and uncompromising quality standards.

For counterfeit LED detection, please contact:

Kinglight Product Testing & Certification Center

Phone: +86 159 5112 6625

Email: export57@kinglight.com

Address: No. 288 Guotai North Road, Yangshe Town,

Zhangjiagang, Suzhou, Jiangsu Province, China

Postcode: 215699