In the previous article about Kinglight LEDs for outdoor displays, we give a brief introduction concerning their varieties, application scenarios, and features. Here in this article, we will look further into the raw materials and product design of Kinglight LEDs for outdoor displays to give us a better understanding why these LEDs are ideal for making outdoor displays.

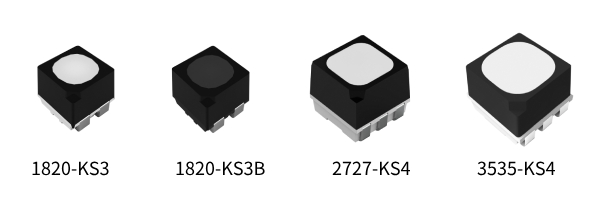

Kinglight KS Series LEDs for high-end outdoor fixed displays

Kinglight LEDs for outdoor displays not only utilize high quality raw material during packaging and also introduce advanced designs for improved performance to cope with complicated and tough outdoor conditions.

Kinglight LEDs for outdoor displays utilize high quality frames, packaging glues, LED chips, and wires to ensure reliability and stability.

1-1. Utilize copper frame to ensure the bonding of frame and the packaging PPA and thermal conductivity; in addition, KS series utilize 99.9% purity copper frames to further enhance structural stability and thermal conductivity.

1-2. Utilize high quality PPA for excellent thermal stability, mechanical strength, and anti-yellowing properties.

1-3. Utilize large LED chips to increase the overall brightness of LED, for example,the red LED chips of KS series LEDs reach 12mil, while blue and green LED chips reach 11*14mil.

1-4. Utilize high-purity copper wiresor gold wires to ensure stable electrical connection; KS flagship series LEDs even use thicker 99.9% high-purity gold wires.

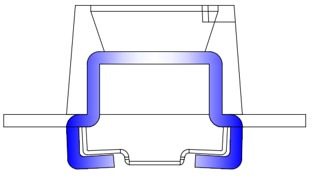

Kinglight LEDs for outdoor displays also adopt advanced technical designs to enhance water proof performance and product stability, such as the stretched cup designs and additional blocking structures to prevent water intrusion.

2-1. Stretched Cup Design

Kinglight LEDs for outdoor displays adopt an unique structural design like stretched cups to prolong the intrusion of water into the inside of the LED modules and to increase their stability at outdoor humid conditions.

Stretched cup design of Kinglight LEDs for outdoor displays

2-2. Additional Water Proof Structures

Kinglight LEDs for outdoor displays utilize additional water proof structures inside the module. As below picture shows, we can see 5 additional structures are applied inside to improve water proof performance of the LEDs.

Additional water-proof structures inside Kinglight outdoor LEDs

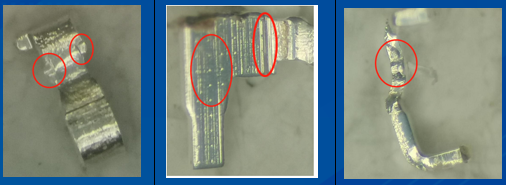

2-3. Unique Wire Bonding

Kinglight LEDs for outdoor display utilize a unique wire boding method named as BBOS to ensure the bondingof the E point; in addition, KS series LEDs adopt curved wire connections to further ensure the stability at the E point.

Curved wire connections inside Kinglight KS series LEDs

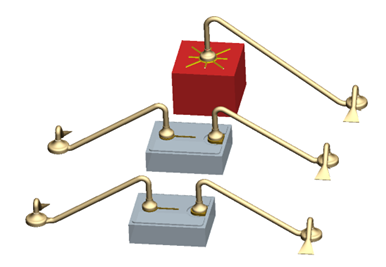

2-4. Raw Material Test

In addition, Kinglight also perform strict test on raw materials to ensure reliable quality of the LEDs, such as testing the bonding between the encapsulation glue and PPA, and systematically verifying and confirming the glue ratio to improve the reliability and stability of the product.

In summary, Kinglight not only offers a wide variety of LEDs for outdoor displays to cover specific application scenarios but also utilizes high quality raw materials and adopts advanced technical designs to ensure their water proof and anti-yellowing performance, and stability, and also excellent performance in energy saving, brightness and display effects.