Quality control (QC) procedures for LED packaging industry typically involve various tests and inspections to ensure that the packages meet specified standards and requirements. To ensure solid performance of our LEDs for LED screen industry, Kinglight follows some common QC procedures for LED packaging like below.

Kinglight LED Packaging – Die Bonding Lines

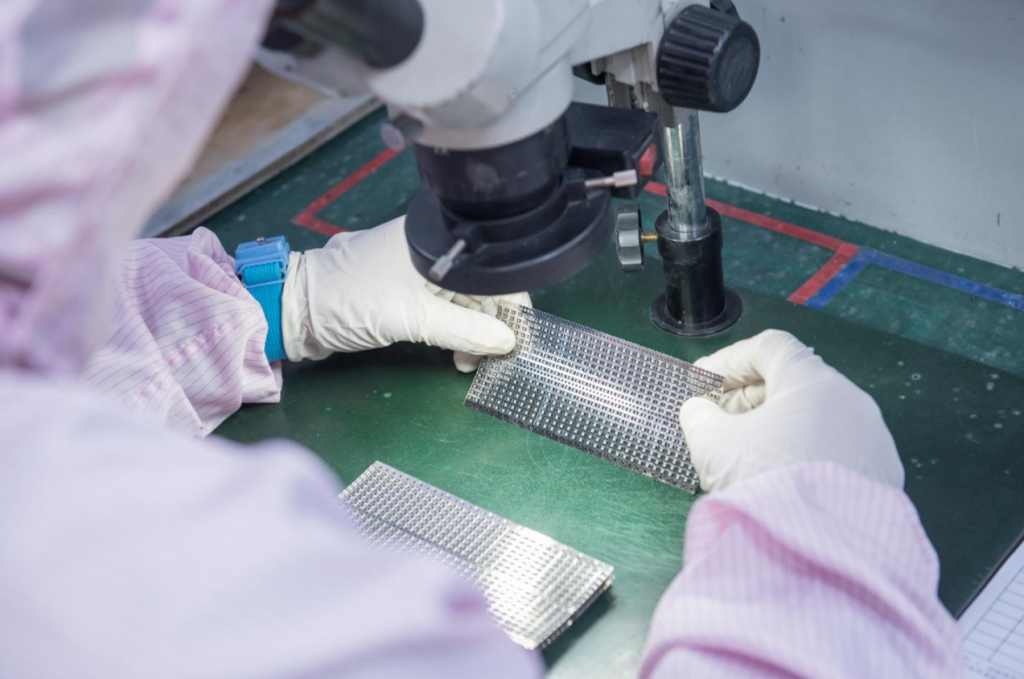

Visual Inspection

Visual inspection involves examining the LED packages for any visible defects such as cracks, scratches, warping, or contamination. This inspection ensures that the packages have a clean and undamaged appearance.

Kinglight QC procedures – visual inspection

Dimensional Measurement

LED packages undergo dimensional measurement to verify that they meet the required specifications in terms of size, shape, and tolerances. This includes measuring dimensions such as length, width, height, lead spacing, and lead thickness.

Lead Integrity Test

The lead integrity test checks the electrical continuity and mechanical strength of the leads or contact pads on the LED package. This test ensures that the leads are securely attached and capable of delivering electrical signals without any interruptions or weak connections.

Electrical Performance Testing

LED packages undergo electrical performance testing to assess their functional characteristics. This includes measuring parameters such as forward voltage, reverse voltage, forward current, luminous intensity, color temperature, and wavelength. These measurements are compared against specified values to ensure compliance with performance requirements.

Kinglight LED Packaging – Electrical Performance Testing

Thermal Resistance Measurement

Thermal resistance measurement assesses the ability of the LED package to dissipate heat effectively. It involves applying a known heat source to the package and measuring the temperature rise. The thermal resistance value is calculated based on the temperature rise and the power applied, providing an indication of the package’s thermal performance.

Kinglight LED Packaging – Thermal Resistance Testing

Moisture Sensitivity Testing

Moisture sensitivity testing evaluates the package’s resistance to moisture absorption and the potential for moisture-related failures. The packages are subjected to controlled humidity and temperature conditions for a specified duration, and their electrical and mechanical properties are assessed before and after the test.

Environmental Testing

LED packages may undergo environmental testing to assess their resistance to various environmental conditions. This can include tests such as temperature cycling, humidity testing, thermal shock testing, and vibration testing. These tests help ensure the packages can withstand harsh operating conditions without degradation or failure.

Reliability Testing

Reliability testing involves subjecting LED packages to accelerated aging tests, such as high-temperature operation or extended stress testing, to assess their long-term reliability and lifespan. These tests help predict the package’s performance and durability over time.

Kinglight LED Packaging – Aging Test

The above mentioned procedures are some typically seen methods for quality control in LED packaging industry that Kinglight follows. In fact, some other QC methods can be performed during the production procedures. For example, during the die bonding for LED chips, thrust testing performs to avoid a luck of thrust caused issues; and during the wire bonding procedure, pull test should perform to eliminate quality issues.