Since the consumption of natural resources continues to increase and results in global warming, energy saving becomes an important requirement in all walks of life, and to a certain extent have led to technological innovation. LED screens, as a display technology with a wide range of application scenarios, are no exception. Cold LED screen technology emerged and brought new possibilities for energy saving in the field of LED display. So how do we achieve cold LED screen? Who are developing cold LED screens? Here in this article, let’s look into the world of cold LED screens.

Unilumin Star Diamond Cold LED Screen

According to data from the International Energy Agency (IEA), global energy consumption continues to grow, of which about a quarter of energy consumption comes from the construction and lighting sectors. As an important part of urban nightscapes and large-scale events, the energy consumption of LED displays is becoming increasingly important.

To this end, governments have introduced various relevant policies to encourage and support the green transformation of LED display technology. More and more LED screen companies are turning to col LED screen technology, which promotes energy conservation and emission reduction of LED screens through the deep integration of fine brightness control technology, special protection strategies for environmentally friendly materials, optimized design of internal structure and welding process, and integrated intelligent adjustable heat dissipation system and common cathode drive circuit and other cutting-edge technologies.

Compared with traditional LED displays, cold LED screens have achieved a qualitative leap in energy saving, environmental protection and efficient heat dissipation.

The core advantage of cold LED screen technology lies in its extreme heat dissipation performance, that is, by integrating advanced heat pipe conduction technology, precisely laid out heat dissipation fins, or carefully optimized air duct structure, the working temperature of the LED screen is stably controlled below 50°C, helping the heat dissipation efficiency to jump by more than 30%. It can not only effectively curb the color distortion and light decay caused by high temperature, but also ensure that the LED chip continues to emit light in the best state and extend the overall service life.

In terms of the choice of light source, cold LED screens usually use high-performance LED chips. These chips can not only convert electrical energy into light with higher efficiency, thereby greatly reducing energy consumption while achieving the same brightness on an LED display panel.

In addition, a cold LED screen also adds an intelligent temperature control system, which can sense temperature changes in real time and automatically adjust the heat dissipation strategy of the LED screen to ensure the optimal operating temperature.

At the same time, a cold LED screen will also be equipped with an efficient power management module, which can realize the fine power supply to the LED chip through precise current and voltage regulation, which not only reduces energy waste, but also improves overall energy efficiency.

Through the above series of technological innovations, cold LED screen technology has perfectly improved the energy efficiency, service life and display effect of LED screens.

At present, cold LED screens are widely used in outdoor advertising, sports stadiums and other scenes, and with its advantages of high efficiency, energy saving and high definition, it has been continuously expanded to other fields, such as smart home, smart city and other emerging industries.

At present, many well-known LED screen brands have independently developed different cold LED screen products, such as Unilumin, Cedar Electronics, InfiLED, Ledman, Hikvision, QS Tech, ITC, etc.

As we all know, Unilumin has always been one of the leading companies in the field of LED screens. By overcoming a series of technical difficulties, such as COB, MIP, AM drive, packaging yield, low carbon energy saving, etc., Unilumin has successfully developed the Star Diamond series AM drive soft LED panels.

Unilumin Star Diamond series LED panels cover 0.9mm and 1.2mm pixel pitches, integrates ultra-cold screen technology, ultra-thin design, high integration and standard HDMI interface, and deeply integrates LCD’s flicker-free and scan-free characteristics, as well as LED’s high refresh, fast response, high brightness, wide color gamut, high contrast, long life and seamless splicing large screen and other excellent performance, redefining the future trend of cold LED screen.

As one of the first companies to lay out green ultra-high-definition integrated packaging and large-size LED display technology, Cedar Electronics launched a newly upgraded COB green ultra-high-definition cold screen flagship product at this year’s ISLE exhibition.

This product integrates Cedar’s self-developed low-power cold screen technology to achieve low temperature rise, significant energy saving, excellent heat dissipation, and a cool touch, ensuring that there is no heat sensation at close range, and the screen temperature is still skin-friendly during long-term operation. It is committed to creating a comfortable environment for users. A new realm of extremely comfortable and efficient human-computer interaction.

InfiLED also developed Cold LEDs integrating innovative PCB layout and high-energy-efficiency RGB flip-chip, common cathode LED chip technology, which increases the luminous efficiency of LEDs by 40% and improves temperature rise control by 40% compared with conventional LED screens.

And through the nano-level (≤60nm) high-precision process driver IC, it is possible to realize that under the same brightness output, the surface temperature of the screen is close to the human body’s comfort zone, without significant thermal sensation, and the energy efficiency ratio is increased by more than 50%, significantly reducing energy consumption.

In addition, InfiLED Cold LED is also equipped with high-performance power modules, with a peak efficiency exceeding 92%, far exceeding the industry standard of 85%-88%, which can effectively reduce the operating costs of LED screens.

At the same time, Cold LED technology brings low-temperature operation, which can extend the service life of the LED screen and delay the aging problem of the LED screen and the damage caused by high temperature.

At present, InfiLED WT, WPmk2, DBmk2 (Ultra), Xmk2 (Ultra), ARmk2, RS and other series of products have adopted its latest Cold LED technology and have received good market feedback.

As one of the leading enterprises in the LED display industry, Ledman has also launched the COB ultra-high-definition energy-saving cold screen series of LED screens, which integrates its own patented COB packaging and pixel engine technology to achieve “cooler, more brilliant, more economical, more stable” performance.

It is reported that Ledman cold screen products not only have a significantly lower screen temperature, but also have high protection and high reliability, and are fully adaptable to various application scenarios.

For example, the Thunder Series COB HS saves up to 50% more energy than similar products. The screen temperature is as low as 31.6°C, which is lower than the human body’s comfortable temperature, creating the ultimate comfortable experience. It truly empowers LEDs in terms of technology and scene applications. The screen has stronger product competitiveness and higher application value.

Hikvision has always been an active practitioner of the concept of sustainable development. As early as 2021, Hikvision released the cold screen Pro series of LED products.

In addition, Hikvision has launched its flagship Mirror series cold LED screens, further leading the innovation of cold LED technology.

It is reported that this series of LED screens integrates the three core technologies of “common cathode LED architecture, flip chip technology, and high-precision process drive”. The operating power consumption is reduced by more than 55%, the daily average power consumption is less than 72W/㎡, and the light efficiency is improved. 122%.

It is particularly worth mentioning that Hikvision’s Mirror series LED screens adopt an innovative row-in-one circuit drive scheme, which reduces solder joints by 70%, significantly improves internal welding stability, and reduces surface temperature by about 20% compared with traditional screens. %, even if it runs for a long time, it still maintains an operating temperature of 30°C, bringing users a comfortable and friendly human-computer interaction scene experience.

As a leader in the field of LED display, QS Tech has also developed the Y53 series cold LED screen, which is based on common cathode LED technology, chip-level voltage division and high-efficiency power supply, leading the new trend of energy saving.

It is reported that this series of LED screens can save up to 60% energy compared with traditional outdoor screens. With a unique box structure and high-efficiency energy-saving technology, it can effectively suppress heat and achieve a 16.3% temperature drop on the front of the screen and a 31.7% temperature drop on the back.

In addition, QS Tech has also developed the E28 series LED screen, which uses a die-cast aluminum lamp panel bottom shell to push the heat dissipation efficiency of the screen to a new height, and through an efficient intelligent detection module and a self-developed intelligent voltage regulating power supply, it realizes low-voltage and low-current precise power supply. Compared with traditional outdoor products, its power consumption is reduced by 50%, and the power consumption of a single box in the black screen state is as low as less than 2W, with remarkable energy-saving effects.

Itc has launched a series of indoor COB die-cast aluminum LED products, which are famous for their innovative PWM-SS dual energy-saving technology. Through the intelligent “sleep mode”, the chip power consumption is greatly reduced to 80%, and it supports seamless wake-up without delay. With the help of 4V ultra-low voltage power supply, it can save an additional 25% of energy, and further reduce the energy consumption of unused ICs through dynamic energy-saving technology. At the same time, high TG value plates are selected to ensure excellent heat resistance, moisture resistance and chemical stability. In conventional application scenarios, the screen temperature of the cold LED screen products launched by ITC can be stably maintained at around 30 degrees.

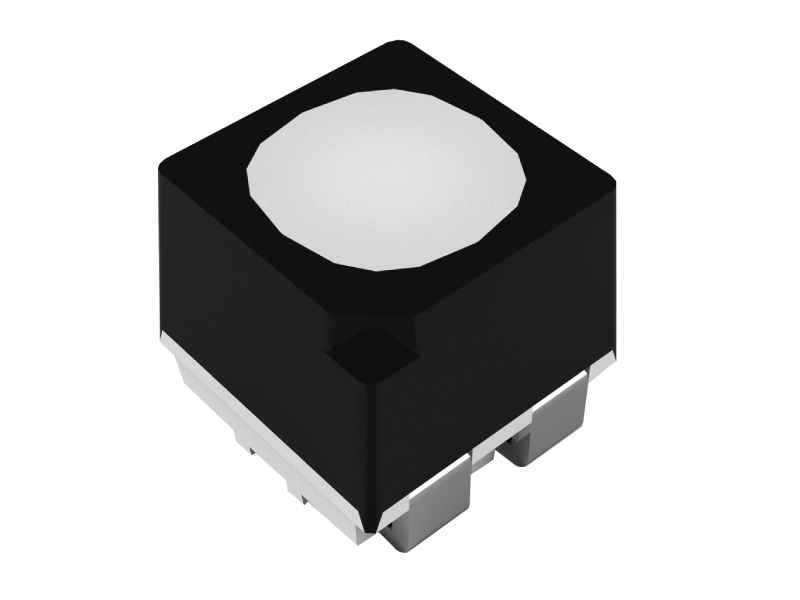

Kinglight 1820N-A1 LED – Common cathode LED for cold screen manufacturing

At InfoComm USA 2024, some media predicted that energy-saving cold LED screen technology will become a trend and lead the new energy-saving standard of LED screens.

With famous brans such as Unilumin, Cedar Electronics, InfiLED, Ledman, Hikvision, QS Tech, and ITC successively are developing cold LED screen technology, it is believed that in the future, more and more LED screen companies will join the competition for cold LED screens.