Pixel pitch of LED displays is a crucial factor you should consider. For outdoors, you may need a LED display with high brightness but less requirement for pixel pitches. Normally, outdoor LED displays exceed P2.0 and higher in pixel pitch. But if you need high definition for stage or indoor display, small pixel pitch LED display is necessary. In recent years, as LED technology evolves, small pixel pitch LEDs has expanded LED display application for indoor usages. As demand for smaller and smaller pixel pitch LED displays raised, Mini LED and Micro LED displays emerged, hence the MiP technology was born and MiP LED displays become more and more popular.

High definition LED display at 2023 Hainan Island International Film Festival

MiP stands for Micro LED in Package, which is a new LED packaging technology based on Micro LED. MiP technology dices Mini/Micro LED panels into small pieces and packages each piece independently. It increases yield and prominently lowers cost for LED display manufacturing.

MiP technology follows a common procedure for LED packaging as below picture shows.

Procedures of MiP Technology

There are two common methods for MiP LED packaging, one is the integrated pixel packaging and the other is the independent pixel packaging.

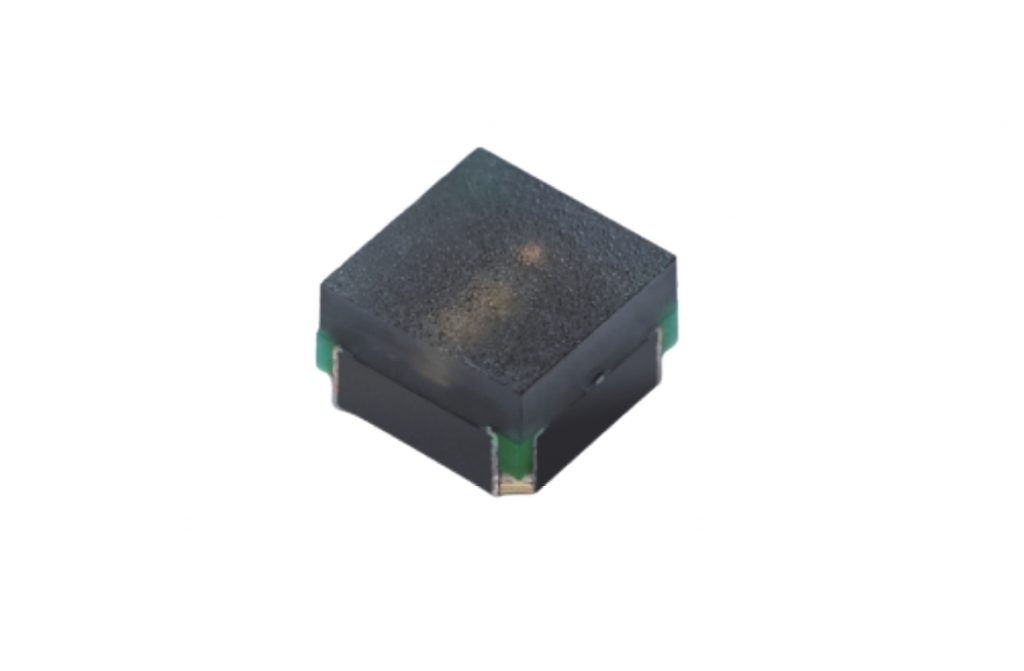

MC0404N-M1

Kinglight MiP series LED display lamps adopt independent pixel packaging technology.

As an innovative packaging technology for Micro LED, MiP enables seamless integration of LED chips and discrete devices and brings Micro LED displays more possibilities and advantages.

With full measurement of Micro RGB pixel, color sorting and mixing, MiP LED display lamps have extremely high brightness, contrast, and color consistency from different viewing angles.

MCOB module based on MiP mounting has consistent ink color and needs no correction through its impeccable light splitting and color mixing features. Much less maintenance is required for MiP LED devices.

Once a bad lamp is detected, it can be removed and replaced easily without affecting the rest lamps on the whole screen.

MiP technology enables mass production to reduce wafer cost while traditional COB technology has strict requirement for mini LED chips, which results in more cost for upstream LED chip factories investing on light and color splitting, bin mixing, etc.

1st, MIP packaging technology complies with existing equipment, which prominently reduces the cost for new equipment and also R&D investment.

2nd, MIP packaging technology effectively decreases defective screening rate and reduces downstream rework costs.

MiP packaging technology gives LED lamps perfect proof of dust, moisture and static electricity.

MiP LED module has better heat dissipation which means less power consumption and temperature rise.

Kinglight MiP0606 LED Display Panel