The LED industry has grown into one of the world’s most important technology ecosystems. From the tiny chips that create light to the advanced displays used in retail, broadcast, transportation, and entertainment, every product relies on a highly coordinated LED supply chain. Understanding this chain helps buyers, integrators, and end-users make better decisions about quality, performance, and long-term reliability.

This article breaks down each stage of the LED supply chain in simple terms and explains how value is added step by step.

The LED supply chain covers all processes required to create LED-based products. It includes raw materials, chip manufacturing, packaging, module production, display assembly, testing, and final delivery to global markets.

Although the chain looks straightforward, every step requires specialized equipment and strict quality control. A weakness in any stage—especially in the chip or LED package—can impact the final display’s brightness, uniformity, durability, and cost.

The supply chain starts in the upstream segment, where LED chips are created on semiconductor wafers.

Manufacturers grow GaN, InGaN or AlGaInP materials on sapphire, silicon, or SiC substrates using MOCVD equipment. This stage sets the foundation for the LED’s efficiency and brightness.

After epitaxy comes wafer cleaning, photolithography, etching, electrode formation and chip separation. The result is millions of tiny LED chips ready for packaging.

Why this stage matters:

Chip quality directly affects color consistency, energy efficiency, and long-term reliability—especially for small-pixel LED displays and MicroLED applications.

The midstream segment transforms bare chips into usable display-ready components.

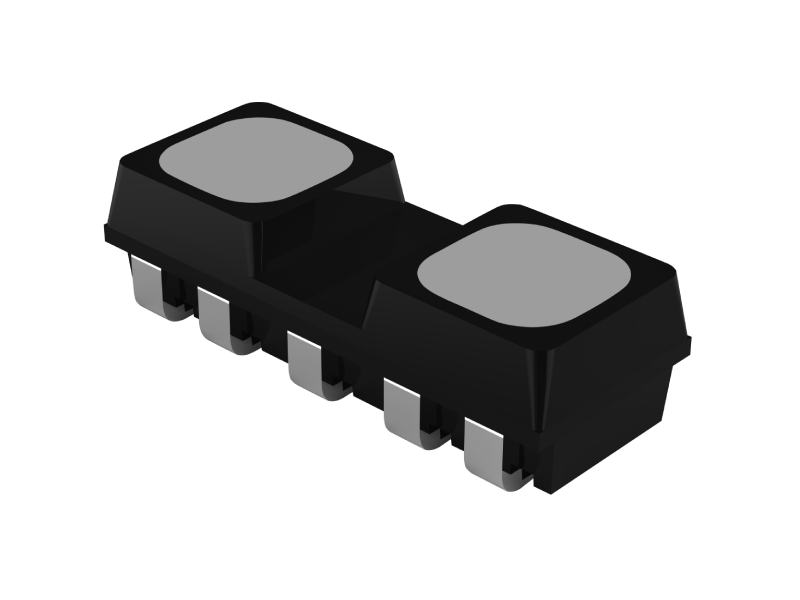

Surface-mounted devices remain the most widely used in LED displays. The process includes die bonding, wire bonding, phosphor coating, encapsulation, and reflow-solderable packaging. Well-designed SMD LEDs offer stable performance for indoor, outdoor, and fine-pitch applications.

Chip-on-Board (COB) mounts LED chips directly onto a PCB or substrate, followed by collective encapsulation (rather than forming discrete LED packages).

Flip-chip designs remove wire bonding and improve thermal and electrical performance.

These technologies are popular in high-density and small-pitch displays that require strong surface durability and higher reliability.

MicroLED refers to LED chips at micron scale, which can be integrated using processes such as mass transfer, COB, or COG.

It is not a packaging form by itself but a chip architecture.

Although still developing, it represents the future of ultra-fine-pitch LED displays.

Why this stage matters:

The packaging stage determines luminous efficiency, heat dissipation, moisture resistance, and color uniformity—all key factors for professional displays.

After packaging, LED components are integrated into display modules and full screens.

SMD LEDs or chip-level COB structures are mounted onto PCBs, followed by soldering, mask assembly and aging tests.

Modules handle pixel arrangement, brightness control and protection.

Modules are installed into cabinets with power supplies, receiving cards, cables and frame structures. Cabinet precision affects flatness and long-term stability.

Finally, cabinets are installed onsite and calibrated through brightness, chroma, and geometric correction systems. The display is now ready for control systems and content playback.

Why this stage matters:

Even the best LED chips or packaging technologies cannot overcome poor cabinet design, weak power systems or inconsistent calibration.

Every step of the LED supply chain requires strict testing. Key tests include:

A strong supply chain ensures consistent performance, lower failure rates and better total cost of ownership for end-users.

The LED landscape continues to evolve. Current trends include:

Growth in fine-pitch and consumer displays is pushing suppliers to improve chip efficiency and expand mass-transfer capabilities.

Outdoor DOOH screens require LED components with better heat dissipation and extreme-weather durability.

Governments and enterprises now prioritize low-power LED displays, influencing chip and driver IC development.

More companies are integrating chip, packaging and display manufacturing to reduce costs and increase control over quality.

A clear understanding of the LED supply chain helps buyers:

For integrators and distributors, it also strengthens communication with end-users and builds trust.

The LED supply chain is a complex yet highly coordinated system that transforms semiconductor materials into high-performance LED displays seen around the world. From epitaxy to packaging, module production and final installation, every stage adds value and impacts display quality.

By understanding how the supply chain works, buyers and industry professionals can make smarter decisions, improve project outcomes, and select LED components that deliver long-lasting performance.