An LED package refers to the assembly that contains the Light-Emitting Diode (LED) chip, electrical connections, and other necessary components to operate the LED. It encapsulates the LED chip and provides protection, electrical connections, and thermal management for optimal performance and longevity.

The LED package typically consists of the following elements:

LED Chip: The LED chip is the core component that emits light when an electric current passes through it. It is a semiconductor device that converts electrical energy into light energy.

Encapsulation Material: The LED chip is encapsulated within a transparent or translucent material, often epoxy or silicone, to protect it from external elements such as moisture, dust, and physical damage. The encapsulation material also helps to enhance light transmission and diffusion.

Electrical Connections: The LED chip is connected to the external circuitry through wire bonds or surface mount connections. These connections provide the electrical pathway for current to flow into the LED chip, powering it and enabling light emission.

Lead Frame or Substrate: The LED chip and wire bonds are typically mounted onto a lead frame or substrate, which provides structural support and electrical connectivity. The lead frame or substrate is often made of metal or ceramic materials that offer good heat dissipation.

Phosphor Coating (for White LEDs): In the case of white LEDs, a phosphor coating is often applied to the LED chip or encapsulation material. The phosphor converts a portion of the blue light emitted by the LED chip into other colors, such as yellow, red, or green, resulting in a broader spectrum and the perception of white light.

Optics (Optional): Some LED packages may include additional optics, such as lenses or reflectors, to control and direct the light emitted by the LED chip. These optics help shape the light distribution, improve efficiency, and enhance the desired lighting effects.

LED packages come in various types and form factors, including surface-mount packages (SMD), through-hole packages (THD), chip-on-board (COB) packages, and high-power packages. Each type has its own advantages and is suitable for specific applications and mounting methods.

The design and selection of LED packages depend on factors such as desired brightness, color, power requirements, thermal management, and specific application needs. LED packages play a crucial role in determining the performance, reliability, and efficiency of LED lighting products and systems.

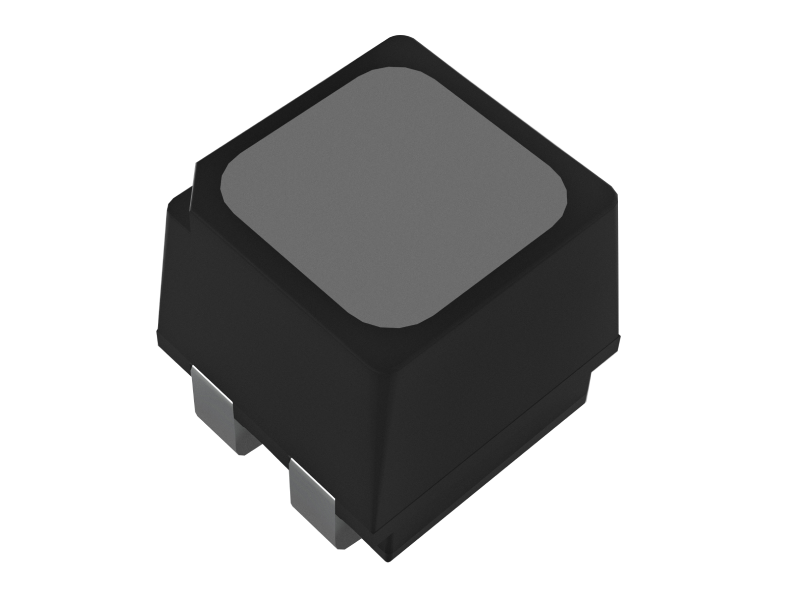

A surface mount package, also known as a surface-mount device (SMD), is a type of electronic component that is mounted directly onto the surface of a printed circuit board (PCB) [1]. This method of mounting components has largely replaced the traditional through-hole technology due to its advantages in terms of cost, quality, and increased component density on a given area of the PCB [1].

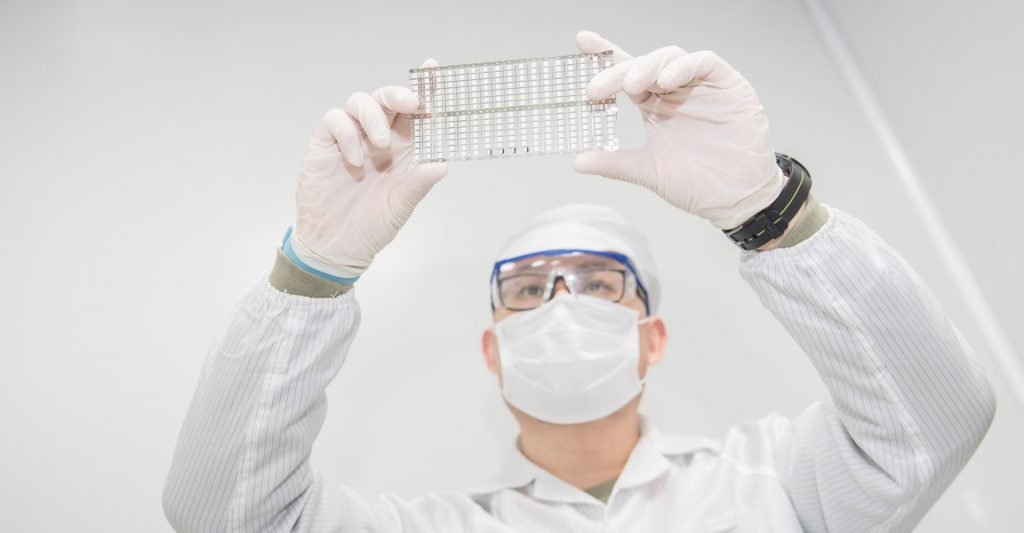

Kinglight offers a wide variety of SMD LEDs for displays

Surface mount packages come in a wide range of shapes and sizes and are designed to be placed by machines rather than by hand. They are commonly used for passive two-terminal components such as resistors and capacitors, which are essential in electronic devices like mobile phones and tablets [2]. These components are available in various physical sizes, with the smallest being the 01005 package (0.4mm x 0.2mm) and even smaller 008004 parts (0.25mm x 0.125mm).

Identifying the value of surface mount components can be challenging due to their small size. The value is usually indicated by a code on top of the device, and there are resources available, such as videos and tables, to help decode these markings.

Surface mount packages are typically mounted on the PCB using solder paste, which is a sticky mixture of flux and tiny solder particles. The PCB is then subjected to a reflow soldering process, where the solder is melted to bond the component leads to the pads on the circuit board.

Through-hole packages are a type of integrated circuit packaging that uses holes drilled through the printed circuit board (PCB) for mounting the components. The components have leads that are soldered to pads on the PCB to electrically and mechanically connect them to the PCB.

Through-hole LED

Advantages of Through-Hole Packages:

Durability: Through-hole components are mechanically secured to the PCB, making them more resistant to mechanical stress and vibrations.

Heat Dissipation: Through-hole packages often have larger leads or metal tabs that can help dissipate heat more effectively.

Repairability: Through-hole components can be easily replaced or repaired since they are not directly soldered to the PCB surface.

Types of Through-Hole Packages:

Dual In-Line Package (DIP): This is a common through-hole package with two parallel rows of pins or leads. DIP packages are available in various pin counts, such as 8-pin, 14-pin, or 16-pin.

Single In-Line Package (SIP): Similar to DIP, but with a single row of pins or leads.

Zigzag In-Line Package (ZIP): This package has a zigzag pattern of pins or leads, allowing for higher pin density in a smaller footprint.

Transistor Outline (TO) Package: These packages are used for discrete components like transistors and diodes. They have a metal or plastic case with leads extending from the bottom.

A Chip on Board (COB) package is a method of circuit board manufacturing where integrated circuits (ICs) are directly attached to a printed circuit board (PCB) and covered with epoxy. This packaging technique eliminates the need for individual semiconductor device packaging, resulting in a more cost-effective, lightweight, and compact final product [1].

Construction:

Flip chip: In this method, the IC is inverted, and small balls of solder are placed on the circuit board traces. The chip and board are then passed through a reflow soldering process to establish electrical connections.

Wire bonding: The chip is attached to the board with an adhesive, and each pad on the device is connected with a fine wire lead that is welded to the pad and the circuit board.

Glob-top: This variant of conformal coating involves depositing a drop of specially formulated epoxy or resin over the semiconductor chip and its wire bonds. It provides mechanical support and protects against contaminants.

Flexible circuit board: Thin flat metal tape leads are attached to the semiconductor device pads and then welded to the PCB.

COB LED modules:

COB technology is also used in LED lighting. COB LED modules contain arrays of light-emitting diodes that are encapsulated in a layer of silicone containing phosphor. This encapsulation converts the blue light of the LEDs into white light. The COB LED module is typically built on an aluminum PCB for efficient thermal management.

Advantages of COB

1. Compact size and weight

2. Improved electrical performance with shorter electrical paths

3. Good thermal management due to direct connection to heat sinks or thermal pads

4. Enables miniaturization and integration of electronic systems

5. Cost-effective solution

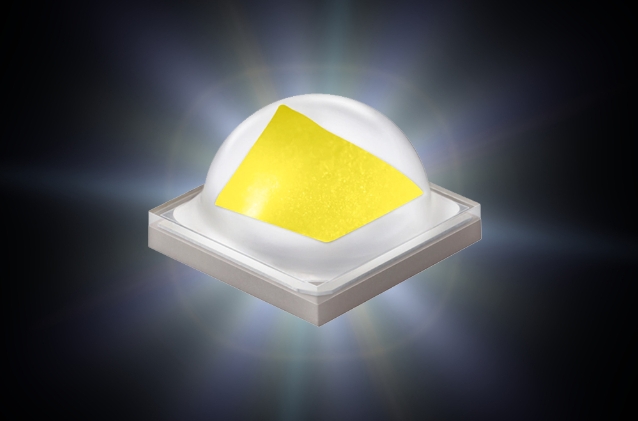

A high power LED package refers to a type of LED module that is designed to produce a significant amount of light output. These packages are commonly used in various lighting applications, including professional outdoor lighting, high-bay lighting, streetlights, floodlights, and more.

Here is some information about high power LED packages:

Features and Benefits

High efficacy: High power LED packages offer excellent energy efficiency, producing a lot of light output while consuming less power.

Compact design: These packages are designed to be compact, allowing for flexible integration into different lighting fixtures and applications.

Long lifespan: High power LED packages typically have a long operational lifespan, reducing the need for frequent replacements.

Versatility: They are available in various color options, including white LEDs and color LEDs, allowing for customization based on specific lighting requirements.

Types of High Power LED Packages

LUXEON 5050 LEDs: These high power white LEDs from Lumileds offer a combination of high efficacy and compact design. They are suitable for outdoor professional lighting applications such as high-bays, streetlights, area lights, and floodlights.

DURIS® S 8: This 5050 leadframe package from ams OSRAM provides impressive efficacy performance and is ideal for high efficacy and compact luminaire designs in outdoor professional lighting applications.

How to Use High Power LED Packages

Power requirements: High power LED packages typically require a constant current power supply to ensure optimal performance and longevity.

Thermal management: Due to their high power output, these packages generate heat. Proper thermal management, such as using heat sinks or thermal pads, is crucial to maintain the LED’s performance and lifespan.

Wiring and polarity: It is important to correctly wire the LED package, ensuring that the anode (positive side) and cathode (negative side) are connected properly to the power supply. Polarity markings are usually provided on the LED package for easy identification.