LED encapsulation is the process of protecting the LED chip and other internal components by enclosing them in a protective material or package. Here are some commonly used terminologies related to LED encapsulation and their meanings.

Las Vegas Strip – LED display technology plays a more and more important role in modern cities.

LED Chip:

The LED chip is the core component of an LED, responsible for emitting light when an electric current passes through it. It is typically a small semiconductor device made of materials such as gallium nitride (GaN) or indium gallium nitride (InGaN).

LED Package:

The LED package refers to the housing or enclosure that protects the LED chip and other components. It provides mechanical support, thermal management, and protection against environmental factors. LED packages come in various forms, such as through-hole packages, surface-mount packages, and chip-on-board (COB) packages.

Epoxy Encapsulation:

Epoxy encapsulation involves using epoxy resin to encapsulate the LED chip and wire bonds. Epoxy is a common material choice due to its transparency, good adhesion, and ability to protect against moisture and mechanical stress.

Kinglight applies epoxy for LED chip encapsulation

Silicone Encapsulation:

Silicone encapsulation is an alternative to epoxy and involves using silicone-based materials to encapsulate the LED chip. Silicone offers better thermal stability and higher resistance to UV light and high temperatures compared to epoxy. It is often used in high-power LEDs and outdoor applications.

Phosphor Coating:

Phosphor coating is a layer of phosphor material applied to the LED chip or the inside of the LED package. Phosphors are substances that convert the blue or ultraviolet light emitted by the LED chip into different colors, such as white or various colors for RGB LEDs.

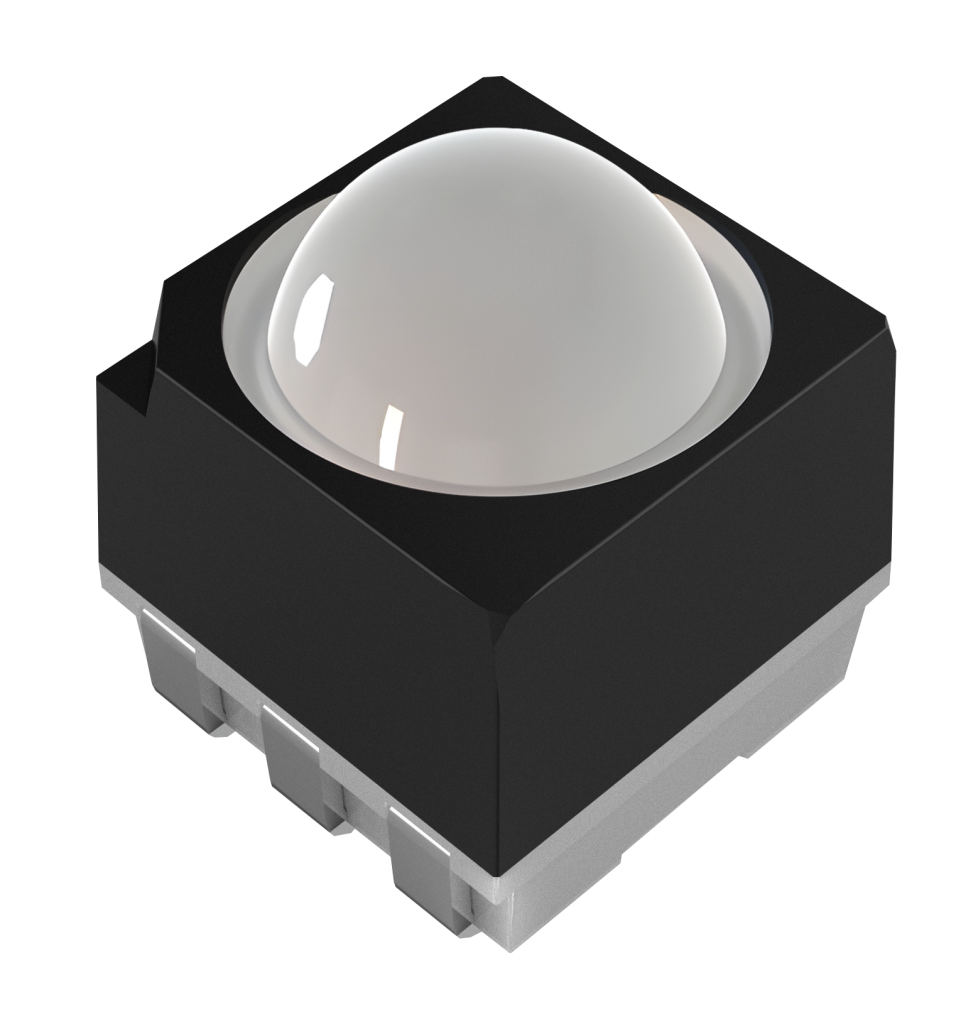

Lens/Dome:

The lens or dome is a transparent cover on top of the LED package that helps shape and direct the emitted light. It can provide optical control, such as beam angle adjustment or color mixing for RGB LEDs, and protection against dust and physical damage.

Kinglight SMD 2727-A4-T70 LED adopts a transparent dome design for 14,000 nits brightness, which is perfect for fixed outdoor LED displays

Lead Frame:

The lead frame is a metal structure inside the LED package that provides electrical connection between the LED chip and the external circuits. It typically consists of thin metal leads or pins that are bonded to the LED chip.

Wire Bonding:

Wire bonding is the process of connecting the LED chip to the lead frame or other electrical contacts using thin wires made of gold or aluminum. It establishes the electrical connection required for the LED to function.

These terminologies are commonly used in the LED industry to describe various aspects of LED encapsulation and packaging. Understanding these terms can help in selecting the appropriate LED package and understanding the characteristics of LED products.