Glass substrate is indeed considered a promising material for the future of mini and micro LEDs. Here’s why:

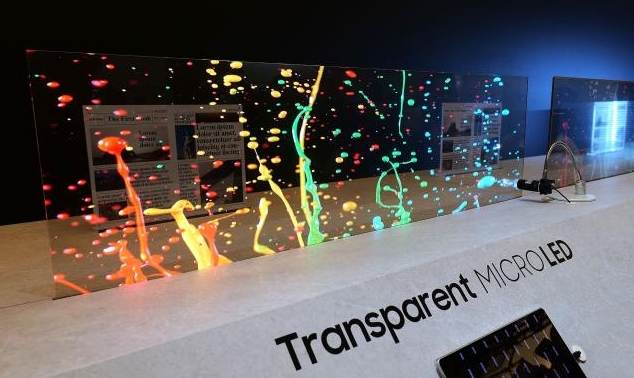

Samsung launches the first transparent Micro LED at CES 2024

High Thermal Conductivity:

Glass has excellent thermal conductivity properties, meaning it can efficiently dissipate heat generated by mini and micro LEDs. Effective heat management is crucial for LED devices as it can impact their performance, lifespan, and stability. Glass substrates help in maintaining lower operating temperatures, enhancing the overall efficiency and reliability of mini and micro LEDs.

Dimensional Stability:

Glass exhibits high dimensional stability, meaning it maintains its shape and structure under varying temperatures and environmental conditions. This stability is important for mini and micro LEDs, as it ensures accurate alignment and positioning of the LED chips during manufacturing and assembly processes. It helps prevent issues like warping or deformation that can negatively affect the performance and reliability of the LEDs.

Transparency:

Glass substrates can be manufactured to have high transparency, allowing light to pass through with minimal interference. This transparency is beneficial for mini and micro LEDs, as it enables efficient light transmission and reduces optical losses. It enhances the brightness, color accuracy, and visual quality of the LED displays or lighting systems.

Scalability and Cost:

Glass substrates offer the potential for large-scale and cost-effective production of mini and micro LEDs. Glass can be manufactured in large sheets or rolls, allowing for efficient fabrication processes and high-volume manufacturing. This scalability helps in reducing production costs and making mini and micro LED technology more accessible for various applications.

Integration with Other Technologies:

Glass substrates can be combined with other technologies to enhance the performance and functionality of mini and micro LEDs. For example, glass can be processed to have microstructures or optical elements that improve light extraction efficiency or enable light guiding effects. It can also be used in combination with flexible substrates or thin-film encapsulation techniques to create bendable or conformable LED displays.

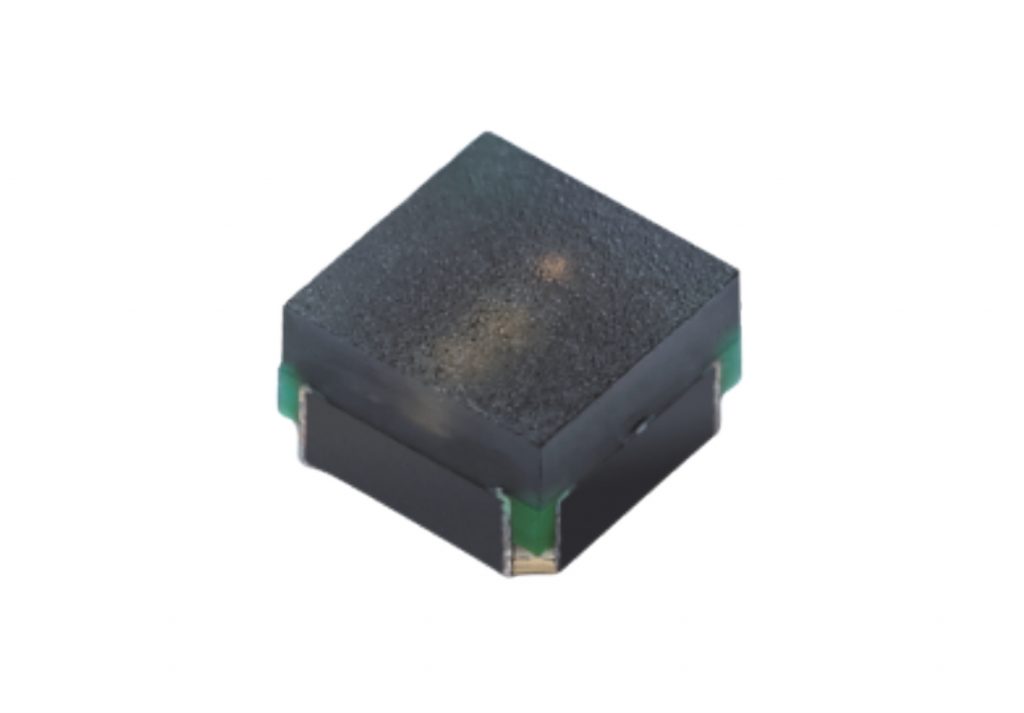

Kinglight MC0404N-M1 Micro LED

While glass substrates offer several advantages for mini and micro LED applications, it’s worth noting that the technology is still evolving, and other substrate materials like silicon or flexible polymers also have their own unique benefits. The choice of substrate depends on specific requirements, manufacturing processes, and the intended applications of mini and micro LEDs.