GOB and COB led displays are two popular options for LED display on the market. They’re two different LED displays under different methods of LED chip encapsulation. GOB stands for Glue-On-Board technology, and COB is an abbreviation for Chip-on-Board technology. In this article, we’ll go through what GOB and COB technologies are, and what features and advantages they bring to GOB and COB LED displays.

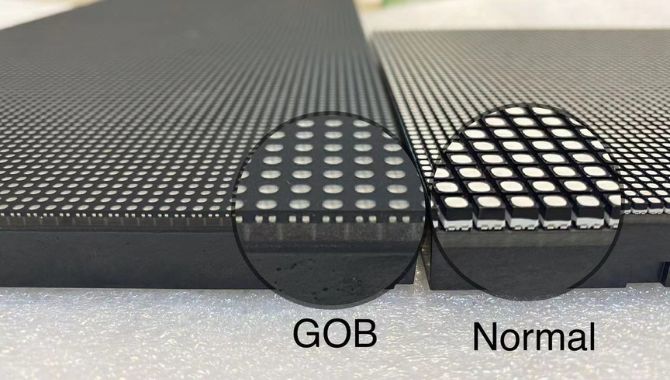

As above mentioned, GOB stands for “Glue-On-Board,” and a GOB LED display refers to a type of LED display technology that utilizes a glue-on-board encapsulation method. In a GOB LED display, a layer of epoxy resin or glue is applied directly onto the LED module, covering and protecting the individual LED chips.

The primary purpose of using the GOB technology is to enhance the durability and reliability of LED displays, particularly in outdoor and harsh environment applications. The glue layer provides protection against moisture, dust, impact, and other external factors that may potentially damage the LED module.

GOB LED display vs SMD LED display

Here are some key features and advantages of GOB LED displays:

Enhanced Protection: The GOB encapsulation method offers improved protection to the LED chips, making them more resistant to water, dust, and physical damage. This enhances the display’s lifespan and reduces the risk of failure.

Weather Resistance: GOB LED displays are designed to withstand various weather conditions, including rain, snow, and extreme temperatures. The glue layer acts as a barrier, preventing moisture penetration and enhancing overall weather resistance.

Improved Contrast and Color Uniformity: The GOB technology helps to reduce light leakage between adjacent LED pixels, resulting in better contrast and color uniformity across the display surface. This enhances the visual quality and viewing experience.

Impact Resistance: The glue layer provides additional protection against physical impact, making GOB LED displays more robust and less prone to damage from accidental impacts or vandalism.

Easy Maintenance: The GOB encapsulation simplifies maintenance and cleaning processes as the epoxy layer protects the LED chips from direct contact, reducing the risk of damage during cleaning operations.

While GOB LED displays offer enhanced protection and robustness, they may have slightly thicker modules compared to other display technologies. This can affect the overall thickness and weight of the display.

GOB LED displays are commonly used in outdoor advertising, sports stadiums, transportation hubs, and other applications where durability and weather resistance are crucial.

A COB LED display refers to an LED display that utilizes COB (Chip-on-Board) technology for its construction. In a COB LED display, the individual LED chips are directly mounted onto a circuit board without individual packaging, forming a densely packed array of LED chips.

The COB LED display technology offers several advantages:

Compact Design: COB technology allows for a compact and space-saving design since the LED chips are closely packed together on the circuit board, eliminating the need for individual packages.

High Density: COB LED displays can achieve a high pixel density, meaning more LED chips can be packed into a smaller area. This results in improved resolution and enhanced image quality.

Uniform Lighting: The closely packed LED chips in a COB LED display provide uniform lighting across the display surface, resulting in better color consistency and reduced color variations.

Improved Heat Dissipation: The direct contact between the LED chips and the circuit board enables efficient heat dissipation. The circuit board acts as a heat sink, helping to dissipate heat generated by the LEDs, which can improve the overall performance and longevity of the display.

Energy Efficiency:COB technology can contribute to energy efficiency due to improved electrical conductivity and heat dissipation. This can result in reduced power consumption and increased energy savings.

COB LED displays are often used in indoor applications where high resolution and image quality are essential, such as in digital signage, commercial displays, and indoor advertising. The compact design and high pixel density make COB LED displays suitable for applications where space is limited, and close viewing distances are common.

COB LED displays also have some shortcomings, for example, their limitations in terms of repairability or individual LED replacement since the LED chips are not individually packaged. However, advancements in COB manufacturing techniques have addressed some of these concerns, making COB LED displays a popular choice in the LED industry for specific applications.

Kinglight LED display lamps contributed for the beautiful floor LED display at Hangzhou Asian Games.

Both GOB and COB LED displays have their respective advantages and are suitable for different applications. GOB LED display is often preferred for outdoor displays where ruggedness and weather resistance are priorities. COB LED display, on the other hand, is commonly used in indoor displays where high density, miniaturization, and cost-effectiveness are important factors to consider.