When it comes to LED displays, pixel quality fundamentally defines the visual performance, reliability, and user experience. Whether you’re equipping a cinema, production studio, retail space, or outdoor installation, selecting the right LEDs can make all the difference. This post outlines the five essential questions to ask your supplier about LED pixel quality—and highlights how Kinglight’s advanced LED offerings stand out.

Why it matters: The stability and durability of an LED display hinge on the quality of materials (e.g., wire bonding) and precision in manufacturing.

Kinglight advantage:

According to Kinglight, LEDs using gold bonding wires deliver exceptional reliability and resistance to corrosion—especially in harsh, salt-laden environments—compared to copper options. This ensures stable electrical conduction over time. Moreover, Kinglight emphasizes the use of premium materials, advanced production processes, and stringent quality control to assure consistent performance.

Kinglight 2727 RGB LED

Why it matters: Not all LEDs are created equal; different applications demand different characteristics—like brightness, contrast, ruggedness, or color accuracy.

Kinglight’s product lineup:

Kinglight classifies its Display LEDs into seven tailored categories:

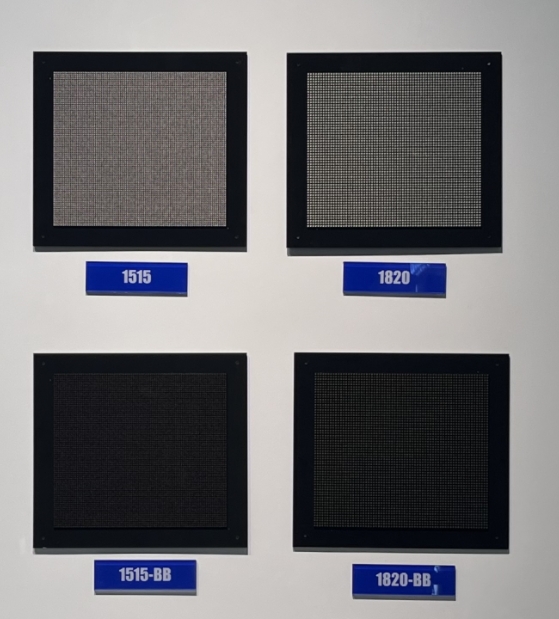

Why it matters: Pixel density (pixel pitch) determines the visual clarity and optimal viewing distance for the display.

Understanding pixel pitch:

Pixel pitch (e.g., P1.25, P5.0) indicates the distance between adjacent LEDs in millimeters. Smaller pitch means higher density and finer detail—useful for close-up viewing.

Viewing distance rule of thumb:

Why it matters: Brightness ensures visibility in different light conditions; heat can degrade LEDs; environmental factors impact longevity and consistency.

Factors and considerations:

Kinglight relevance:

Kinglight’s Fixed Installation and Outdoor 8K categories are engineered for high brightness and efficient long-term operation, indicating robustness in real-world conditions.

Why it matters: Rigorous testing ensures uniform performance and minimizes defects.

Kinglight’s approach:

Kinglight emphasizes a full-process quality control system, leveraging advanced manufacturing and comprehensive inspection to ensure each batch meets high standards. Kinglight’s commitment to stringent testing is central to delivering stable, long-lasting LED products.

Kinglight 1515 and 1820 LEDs with different contrasts

Asking these five questions—on materials/assembly, product categorization, pixel pitch vs. viewing distance, brightness/thermal/environmental stability, and quality control—helps ensure you select LED pixels that perform beautifully and reliably across diverse use cases. Kinglight exemplifies these best practices, offering a diverse range of LEDs tailored to rental, cinema, XR, outdoor, fixed, and creative installations, backed by strong materials and quality assurance.