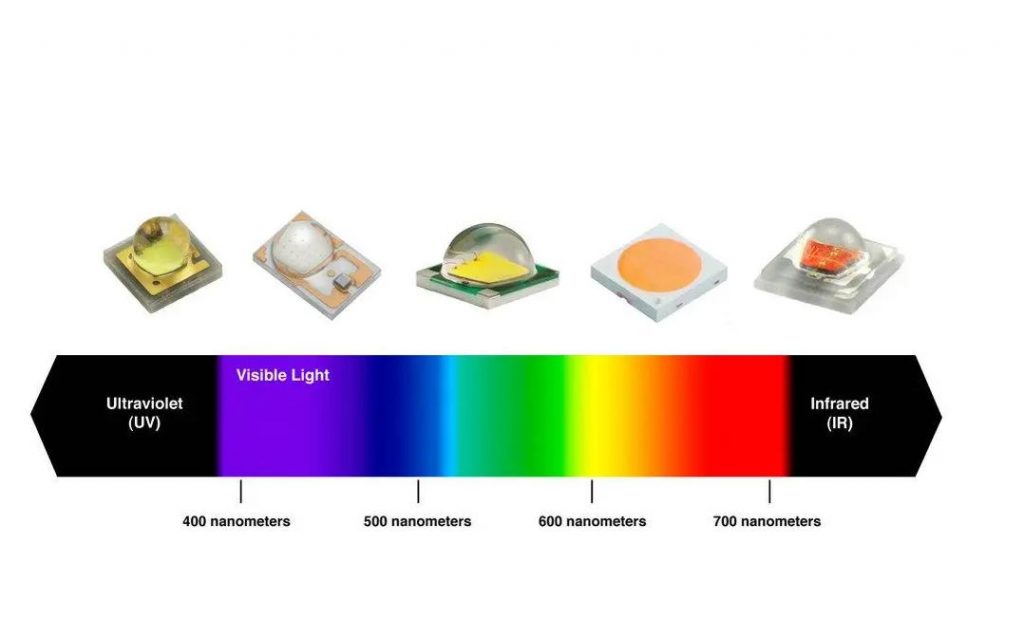

LEDs are quite common in our daily life. The lamps in your house or at the backyard, and the screens on wall surfaces of shopping malls and city CBDs, most of them are made of LEDs nowadays. We can see traffic lights in red, green, and yellow colors. What’s behind the different colors of LED? That’s what we’ll talk about today, the wavelength of LEDs.

LED wavelengths and light colors

Usually, LED wavelength refers to the wavelengths of the light emitted by the LED. It decides the color of the light emitted by the LED. Red, yellow, green, blue and purple LEDs, as well as special wavelength LEDs such as infrared LEDs and ultraviolet LEDs. Now let’s proceed to the details of wavelengths of LEDs, and their luminous colors and application scenarios, and the way to obtain the wavelength parameters of LEDs.

The wavelength of LED refers to the wavelength of the central light emitted by the LED. Different wavelengths of LED means different light features, some are invisible, such as infrared LED and ultraviolet LED, and others are visible, for example, commonly seen red LED, green LED, and blue LED. Below is the categorization of LEDs in three different wavelength ranges.

Ultraviolet LED (UV): LEDs emit invisible ultraviolet light usually have a wavelength of less than 400nm, including near-ultraviolet with a wavelength between 380 and 400nm, and deep ultraviolet with a wavelength less than 300nm.

LEDs with visible light: LEDs with a wavelength between 400nm and 780nm, usually produces visible lights in red, green, blue, yellow, purple, etc.

Infrared LED (IR): Infrared LED means an LED emits invisible infrared LED. It usually has a central wavelength of over 780nm , which is invisible to our eyes.

And of course, the LED lighting fixtures and LED display screens we use in daily life are all visible light LEDs.

In fact, the wavelength of LED can be further described in peak wavelength and main wavelength. In the actual application of LED, we often need to refer to either the peak wavelength or the main wavelength according to specific application scenarios.

Peak wavelength (λP) refers to the wavelength with the highest spectral output value, that is, the wavelength with the highest radiation power or luminous intensity in the spectrum. It is a pure physical quantity and is usually applied to the detection of monochromatic light with relatively symmetrical waveforms.

The unit of peak wavelength is nanometer (nm). When designing LEDs, peak wavelength is an important reference indicator because it is directly related to the optical properties of LEDs.

The dominant wavelength (λD) is the wavelength corresponding to the color of the main light emitted by the light source that the eye can see. The difference between it and the peak wavelength is that the dominant wavelength takes into account the visual perception of the human eye, that is, the color seen by the human eye.

In the CIE1931 horseshoe coordinates, the wavelength of the intersection of the extended line from a certain point and the horseshoe curve is regarded as the dominant wavelength. The unit of dominant wavelength is also nanometer (nm). Since the light emitted by the light source is usually composed of multiple wavelengths of light, the dominant wavelength reflects the visual impression of these lights after mixing.

So, in practical applications, should we choose the right LED product based on the peak wavelength parameter or the dominant wavelength parameter?

If the LED is used in an optical instrument and needs to identify a specific wavelength, the peak wavelength is the parameter we should refer to.

If the LED is used as backlight for a display or otherwise illuminate or indicating light, the dominant wavelength is the thing we ought to consider.

Wavelength is a decisive factor of the color of the light emitted by an LED. This means, different wavelengths equal different light colors of LEDs.

Common types of LEDs and their wavelength ranges:

Red LED: approximate wavelength range is between 610-700nm.

Orange LED: approximate wavelength range is between 590-610nm.

Yellow LED: approximate wavelength range is between 575-595nm.

Green LED: approximate wavelength range is between 495-570nm.

Blue LED: approximate wavelength range is between 450-490nm.

Purple LED: approximate wavelength range is between 370-410nm.

Ultraviolet LED: approximate wavelength range is less than 380nm.

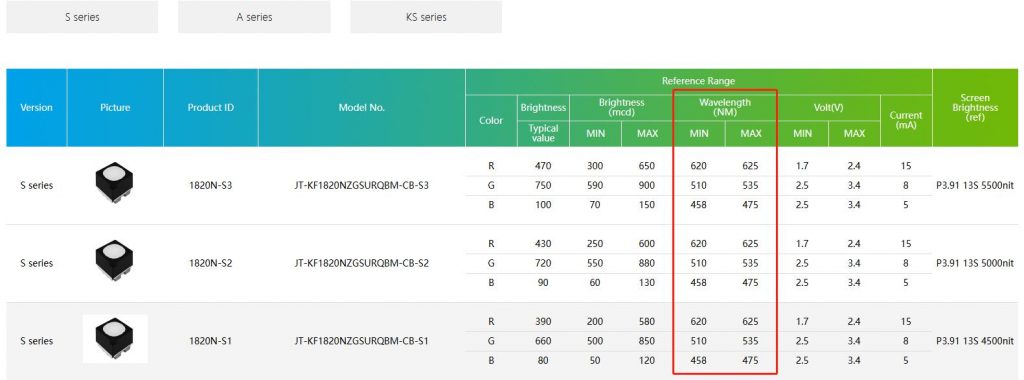

For example, the wavelength of the red LED chip in a Kinglight SMD RGB LED is usually between 620nm and 625nm, the wavelength of the green LED chip is between 530nm and 535nm, and the wavelength of the blue LED chip is limited to between 458nm and 475nm, so as to obtain more accurate red, green and blue primary colors, ensure excellent color mixing effect, and provide excellent color reproduction ability for LED screens.

Kinglight SMD LED – the wavelengths of R,G, and B LED chips are restricted in smaller ranges to ensure accurate primary colors for LED screens

In addition, the light-emitting principle of LED is based on the electronic transition of semiconductor materials. By applying voltage, electrons are stimulated to transition from low energy levels to high energy levels, and then return to low energy levels to release photons. The energy of these photons determines the wavelength and color of light.

Now let’s take a look at the main application scenarios of several common visible light LEDs, including red LED, green LED, blue LED and purple LED.

Red LEDs are mainly used in signal indicators, car taillights, infrared communications, lasers, and biomedical imaging lamps.

In signal indicators, red LEDs are used to indicate stop, warning, and fault light status, and their high brightness and bright colors make the signal indication more eye-catching.

In lasers, red LEDs can be used as light sources for applications such as burning and display.

In addition, red LEDs can also be used in the biomedical field for phototherapy and photodynamic therapy.

Green LEDs are mainly used in outdoor displays, lighting, lawn lights, traffic lights, etc.

In outdoor displays, green LEDs can emit bright green light, making the display effect clearer and fuller.

In the field of lighting, green LEDs are used in landscape lighting and indoor lighting. Their high brightness and energy-saving performance make green LEDs the first choice for lighting products.

In addition, green LEDs are also used in traffic lights, mainly to indicate passage.

Blue LEDs are widely used in indoor lighting, optical communications, medical equipment, etc. In indoor lighting, blue LEDs can be combined with phosphors to emit white light for lighting and display backlighting.

In optical communications, blue LEDs can be used for data transmission with high transmission rates and stability.

In addition, blue LEDs can also be used in medical equipment for the treatment of skin diseases and teeth whitening.

Purple LED is generally used in ultraviolet sterilization, ultraviolet detection, fluorescent light source, etc.

In ultraviolet sterilization, purple LED can emit ultraviolet light, which has strong sterilization ability and can be used in water treatment and air purification lamps.

In ultraviolet detection, purple LED can be used to detect fluorescent substances, minerals and banknotes.

In addition, purple LED can also be used as a fluorescent light source for fluorescent lamps and fluorescent displays.

The main differences between infrared and red LEDs are their visibility, wavelength range, application areas, and functions.

Visibility and wavelength range:

Red LED is visible to the human eye, and its wavelength range is between 600-700nm.

Infrared LED is invisible to the human eye, and its wavelength range is usually between 760 nanometers and 1 mm, far beyond the visible spectrum of the human eye.

Application areas:

Red LED is mainly used in the visible light field, such as LED indicators, display screens, decorative lights, etc., among which the application of red LED also includes medical and beauty fields, because red light can promote cell metabolism and accelerate wound healing.

Infrared LED has a wider range of applications, including communications, detection, military, and medical treatment, among which the medical field uses the thermal effect of infrared LED for high-temperature sterilization and equipment monitoring. In addition, infrared LED is also widely used in biomedicine, chemical analysis and other fields.

Function:

In addition to lighting and display functions, red LEDs are also used in beauty and medical fields because they can promote cell metabolism, help wound healing and enhance immune function.

infrared LED is used in communications, detection, military and other fields due to its invisibility and strong penetration ability. In the medical field, infrared LED is used for high-temperature sterilization and equipment monitoring.

In short, red LEDs are mainly used for lighting and display in the visible light field, while the application of infrared LED extends to multiple fields such as communications, detection, and military. Both are used in the medical field, but the specific functions and application scenarios are different.

The wavelength of an LED is mainly determined by the bandgap width of the material, which is determined by the electronic structure characteristics of the semiconductor material. Specifically, the emission wavelength of LED is related to the bandgap width (Eg) of the semiconductor material, which is calculated according to the formula λ=1240/Eg, where λ represents the emission wavelength and Eg represents the bandgap width.

Changing the bandgap width of the material can be achieved by doping. The mainstream LED products on the market, such as blue LED, are mainly made of GaN, and red LED products are mainly AlGaInP and GaAs. The wavelength range of general LED lamps is between 380-780 nanometers. Below 380 nanometers is ultraviolet LED, and above 780 nanometers is infrared LED. These wavelengths of light are harmful to the human body or exceed the visible range of the human eye.

In addition, the wavelength of LED is also affected by other factors, including:

Mixed crystal formation: The continuous change of emission wavelength can be achieved by forming mixed crystals.

Quantum confinement effect: For devices using quantum well structure, the quantum confinement effect will shorten the emission wavelength.

Polarization electric field: For the InGaAlN material system, the strong polarization electric field makes the emission wavelength longer.

Temperature: As the temperature rises, the wavelength becomes longer.

Stress state: The stress state of the light-emitting layer can change the emission wavelength. Tensile stress makes the wavelength longer, and compressive stress makes the wavelength shorter.

In general, the wavelength of LED is not only determined by the bandgap width of the material, but also affected by many factors, including mixed crystal formation, quantum confinement effect, temperature, stress state, etc.

So, what methods can we use to obtain the specific wavelength parameters of LED? Generally speaking, we can measure the wavelength parameters of LED through methods such as spectrometer, multimeter, X-ray, integrating sphere, etc.

Spectrometer measurement:

Use a spectrometer to measure the spectral distribution of LED, and determine the wavelength of LED by analyzing the spectral curve. This method requires professional equipment and is suitable for laboratory environment.

Multimeter detection:

Although the multimeter is mainly used to detect the quality of LED lamp beads, it can also be used to preliminarily determine the wavelength of LED. By observing the change in voltage reading on the multimeter, the wavelength range of LED can be roughly estimated.

X-ray detection:

X-ray detection technology can be used to detect the internal structure of LED light strips. Although it does not directly measure the wavelength, it is very useful for detecting the quality and structure of LED light strips.

Integrating sphere:

The integrating sphere is a method of measuring total luminous flux. By combining the integrating sphere with a photometer or a spectroradiometer, the spectral information of LED can be indirectly obtained.