LED is the basic component for the manufacturing of LED display panels, which are finally assembled into LED screens. As a humidity sensitive and vulnerable electronic, LED should be packaged to protect from the moisture in the environment, and carefully handled while the packaging procedures, and of course, aging of LED panels or LED displays should also be processed with care to avoid degrade of performance or failures happening on LED pixels. Now let’s follow the guidance of Kinglight LEDs and learn how to correctly use LEDs in packaging, maintain, and do the aging of LED displays.

Kinglight 4093 4-in-1 LED Sample Plate

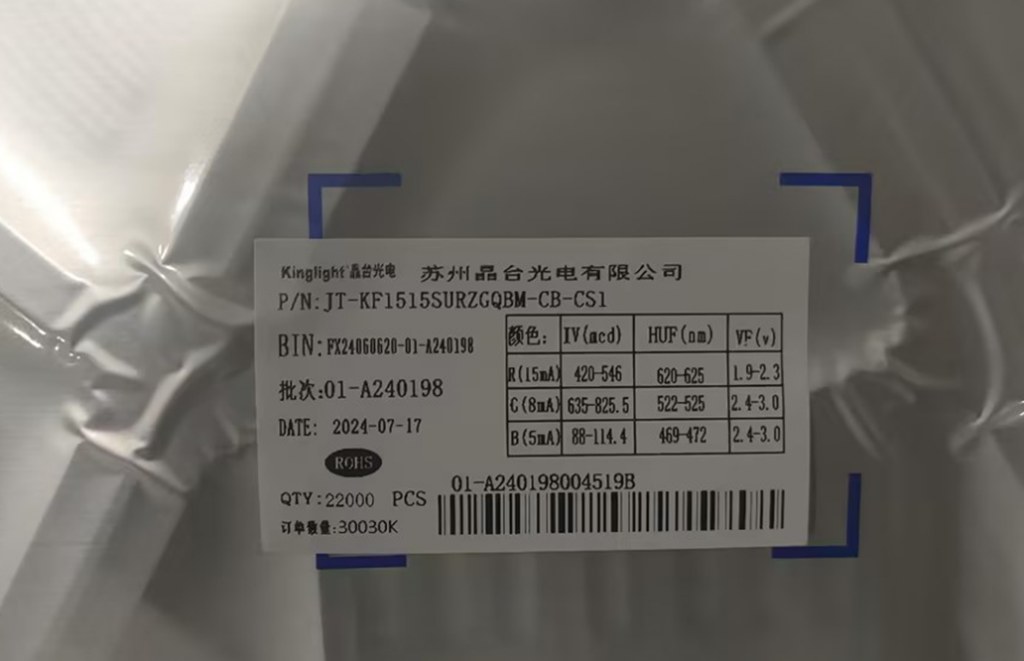

After LED packaging and QC testing procedures complete, LEDs will be well packed in a sealed bag to protect from being damaged before they reach the production lines for LED displays.

Take the label on the aluminum foil vacuum bag of Kinglight LEDs for example, it usually states product ID, BIN, production batch, date, quantity, and product parameters, etc.

3-1. before use, carefully check above information and avoid using LEDs of different ID or bins to avoid color deviation among different LED panels; keep the labels or a record of used LEDs as a trace in the future.

3-2. LEDs of different product IDs can’t be used together.

3-3. LEDs of different production batches can’t be used together even though they have the same product ID and parameters.

Now, let’s proceed to the details we should care while doing SMT operations.

3-1. Welding of LEDs should complete in 12 hours.

3-2. Ensure that the temperature in the production workshop is below 30°C and the humidity is below 60%RH; and prevent contact with the outside world.

3-3. LEDs that have not been used for more than 12 hours need to be re-baked before use.

3-4. Unused LEDs must be stored in an environment with a temperature below 25℃ and a humidity below 30%RH and must be used within 24 hours.

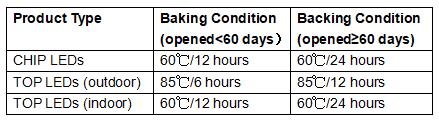

Baking Conditions

This is only for LEDs that have been stored for a long time after opening. It is recommended that LEDs that have been exposed to moisture before opening be returned to the factory for re-baking.

Baking conditions include temperature and duration.

Note: The baking temperature error must be controlled within the range of ±5°C to ensure the baking effect and avoid damage to the LED.

6-1. Operators must wear anti-static wrist straps, anti-static shoes or anti-static gloves, etc.

6-2. All mechanical equipment must be grounded.

6-2-1. The workshop needs to be paved with anti-static flooring and grounded, and use anti-static work mats;

6-2-2. Each machine equipment must be well grounded, and the AC impedance should be less than 1 ohm;

6-2-3. Regularly check whether the machine parameters and power output are qualified, and check whether the test equipment and drive power supply have leakage.

Continue to read:

Guidance for LED Application & Protection (II) >>>