Moisture in the air keeps penetrating into your LED displays, and accumulates day by day, and eventually will affect the functionality of the inside components like LEDs and ICs. In rainy seasons or humid areas, the situation can be worse. Thus, it’s important to keep your LED display dry for a reliable performance and a longer life. Here in this article, we’ll start from the structure of LEDs to step by step learn how to protect your LED display from humidity.

Sphere, a sphere shaped LED architecture in Las Vegas, US

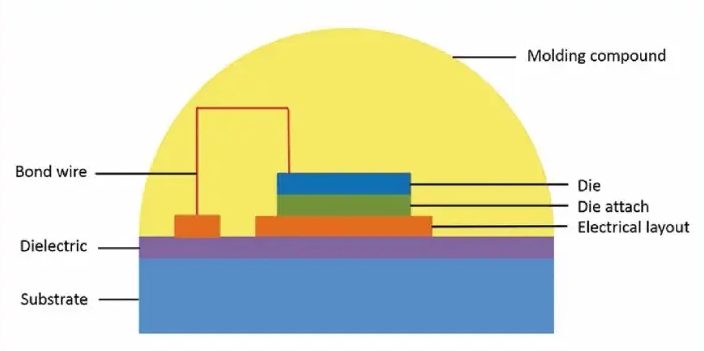

From LED chips to LEDs (for screens), there is a manufacturing process, which is called as LED package.

Diagram of LED Package

LED package involves various of different materials, including encapsulant like epoxy resin to cover and hold LED chip onto the substrate, and gold or copper wires to connect the chip to other functional components, and PPA shell to case and protect all the inside units.

These materials bear different expansion rates. When high temperature is applied during LED package process to bond inside components together, different materials expand in different rate under thermal stress. Delamination tends to happen and tiny gaps appear between them. This allows moisture to penetrate into the inside of LEDs.

In addition, PPA and epoxy resin are polymer materials prone to absorb moisture.

LEDs are vacuum packaged to protect them from moisture and dust.

For example, Kinglight utilizes vacuum bags made of aluminum foil with desiccant and humidity indicator inside.

Kinglight LEDs are packaged in vacuum aluminum foil bags.

If you’re about to use vacuum packaged LEDs, always check if there is a leak before opening the vacuum bags. If so, return to the supplier and they’ll re-bake and dehumidify the products. If not, check the value on the humidity indicator; if the value exceeds 30%, return it to the supplier.

If you’re going to lay them aside, it’s better to store the package at an environment of around 30℃ with humidity under 60% RH. And remember to use them in no more than 6 months.

If you’re a screen manufacturer, always control the temperature at 25±5℃ and humidity between 40%-60% RH at your SMT workshop. And follow the supplier provided guidance to bake all LEDs before SMT processing. And STM processing must be performed within 12 hours after LEDs being baked.

Remained LEDs should be re-packaged in vacuum bags to avoid long time exposure to the air.

If your LED panels are being stored for more than a month, you’d better follow below steps to age and dry them before assembling them into screen displays.

Believe me, it’s worthy to do so though it takes 6 hours.

For different LED displays, there are different ways to protect them from humidity due to their different features.

For indoor fixed screens with an ambient humidity between 10% – 65% RH, at least light up the screen twice a week and no less than 2 hours for each time. If the screen is working in extreme wet environment with humidity over 65% RH, try all your efforts to dry the place.

For stage rental screens, store them in flight cases after use. Put no less than 50g of desiccant into the case. Regularly check if the desiccant works; if not (normally desiccant absorbing too much moisture will turn much deeper in color), replace; regularly replace the desiccant every two months. Avoid water while using the screen; if water splashes onto or goes inside the screens, blow them dry with a hair dryer, and light them up for 2 hours before putting back into the flight case.

For outdoor LED displays operating in ambient humidity between 10% – 85% RH, light them up at least twice a week and no less than 2 hours for each time. If the ambient humidity exceeds 90% RH, light the screen up no less than 3 times a week and more than 3 hours for each time.